After the report by Isofoton regarding reliability testing of Bi-based alloys for tabbing ribbon, the world learned that Bi-based alloys could survive the lamination process and function in use. If you haven’t seen it yet, I consider this mandatory reading! Here is the info: B. Lalaguna, P.Sanchez-Friera, I.J. Bennett, L.J. Caballero, J. Alonso, “Evaluation of Bismuth-Based Solder Alloys for Low-Stress Interconnection of Industrial Crystalline Silicon PV Cells", 22nd EU PVSEC, Milan, 2007Milan, 2007.

We all know the Bi based alloys like 57Bi/42Sn/1Ag and 58Bi/42Sn can be used in a standard module assembly process, but is there an advantage to using Bi/Sn or Bi/Sn/Ag when Sn/Pb and Sn/Pb/Ag alloys are so well known and trusted in the industry?

I’ll give you 3 benefits:

1) 1) Bi/Sn/Ag and Bi/Sn are Pb-Free

3) 3) When paired with the correct flux and metallization, these Bi alloys form a powerful bond without microcracks (due to the lower process temperature)

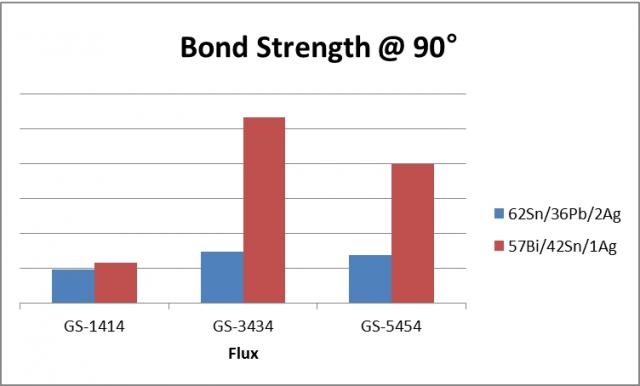

Below are results with SunTabTM ribbon assembled on a Komax X series stringer and tested on a XYZTEC Condor 150-3 bond tester (provided by the respective companies).

You’ll probably notice the lack of y-axis scale – I’m not going to give away all the cool information that easily! Contact me at jhisert@indium.com to learn more.