It is easy to get burned during the burn-in and test process if you don't use the right thermal interface material. In addition to the old-fashioned thermal interface materials, you have two modern, high-performance metal thermal interface material (mTIM) options to from which to choose:

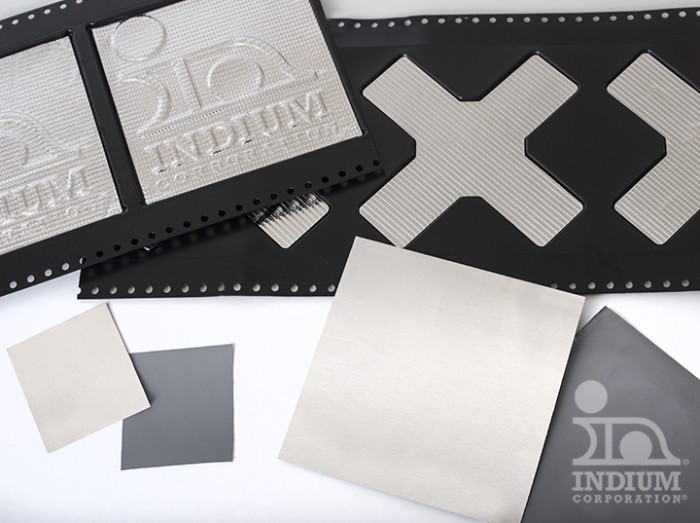

INDIUM Heat-SpringR mTIM:

Indium is the best metal thermal interface material available because it:

-

is highly thermally conductive (86W/m K)

-

is easy and clean to use

-

works for multiple insertions

-

is readily available

-

is well-proven

-

can be recycled

Our Heat-SpringR mTIM's unique pattern provides uniform contact between the chip and the burn-in head, giving you the best thermal conductivity because there are no voids which can produce hot spots.

POLYMER ADHESIVE mTIM:

Another option is our HSMF-OS mTIM. This is a multi-layer aluminum and non-silicone polymer that has a gently-tacky side to help the interface stay in exactly the right place. This material is perfect for applications that are larger in area or that do not require the higher thermal conductivity of indium. There is no pattern in this material, so your surfaces need to be fairly flat. But, it is very durable and will give you a high insertion rate.

You can see both high-performance mTIM options at the BiTS workshop in Phoenix, AZ, March 5-8, 2017. In addition to displaying these products, our burn-in experts will be on-hand to discuss your applications.

We are also co-presenting a paper on "Metallic Thermal Interface Material Selection for Burn-In". And on Monday morning we are sponsoring the Key Note Address to be given by Thomas Sonderman of Integrated Solutions Group.