Eutectic Gold Tin (AuSn) with a composition of 80Au20Sn is a unique material. This particular alloy of gold tin (AuSn) is considered a solder because it has a melting temperature of 280ºC, which is lower than the 350ºC transition temperature into braze materials. Still, there are some similarities between this solder alloy and braze alloys. The most obvious is the hardness of the gold tin (AuSn) alloy. With a tensile strength of 40,000PSI, this solder is much more rigid than the tin solders most are familiar with. The strength is more closely compared to the silver brazes which melt above 500ºC.

With that strength has come some unique manufacturing difficulties. For many years, one obstacle for implementation of gold tin (AuSn) as a solder preform or wire, was its availability in thin forms or fine diameters. The gold tin (AuSn) is extremely hard and it became brittle as it was handled through manufacturing and would crack if it was pressed too thin or fine.

Luckily, in the 40+ years since eutectic gold tin (AuSn) was first used in electronics manufacturing, processing techniques have come a long way. Today, gold tin (AuSn) solder can be made into dimensions much smaller than the soft solders, allowing it to be used in applications which require the highest level of precision.

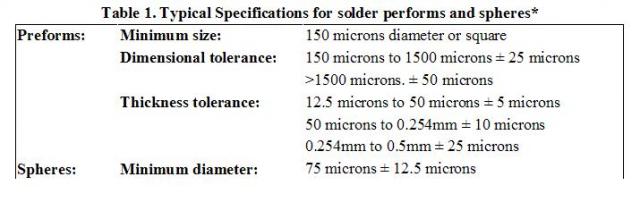

Typical dimensions and tolerances of gold tin (AuSn) can be found in the below chart.

This chart as well as more detail on gold tin (AuSn) applications are available in the paper titled, “Process and Reliability Advantages of AuSn Eutectic Die-Attach,” presented at IMAPS 2009.