During a NanoBond® reaction, assembly pressure may determine if you create a quality solder joint. There are many details that can influence how much pressure is actually needed:

During a NanoBond® reaction, assembly pressure may determine if you create a quality solder joint. There are many details that can influence how much pressure is actually needed:

- NanoFoil® thickness

- Solder type/oxidation/thickness

- Surface roughness

-

Part flatness

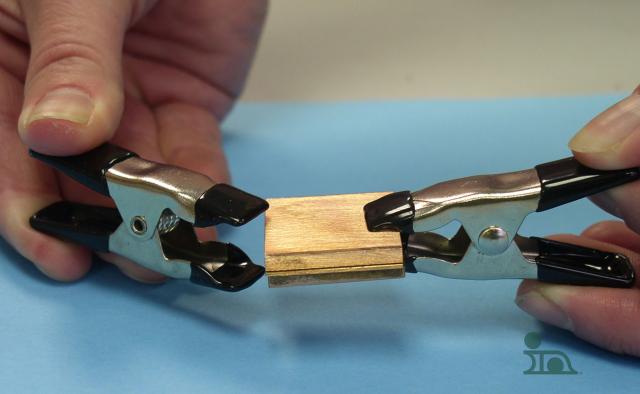

In practice, we use anywhere from a few psi (like the clips shown above) ...

... up to 400-500psi (with a press, as shown below) – depending on the criteria listed above.

The main thing to keep in mind is that you want uniform pressure across your interface.

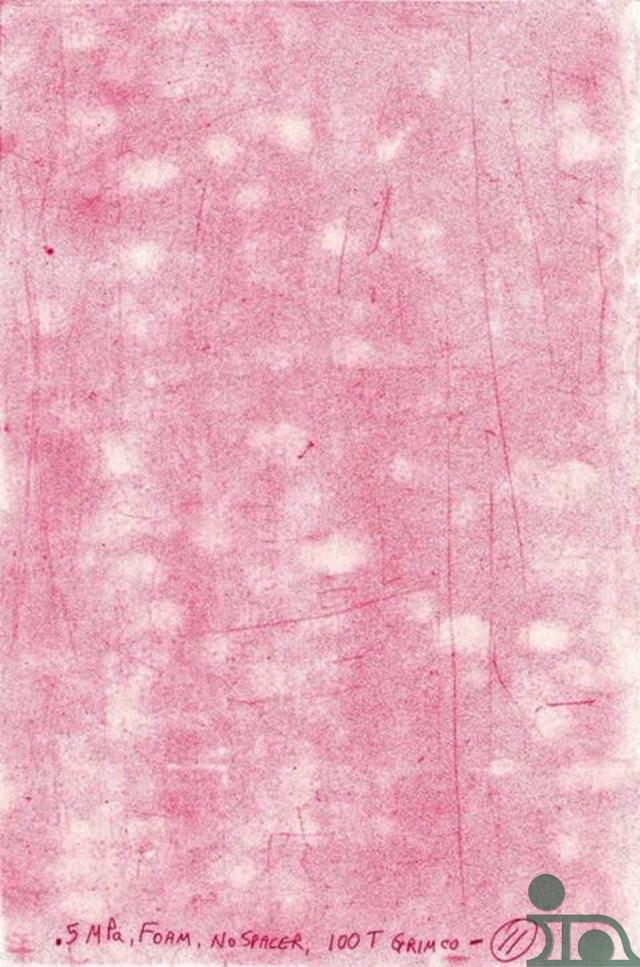

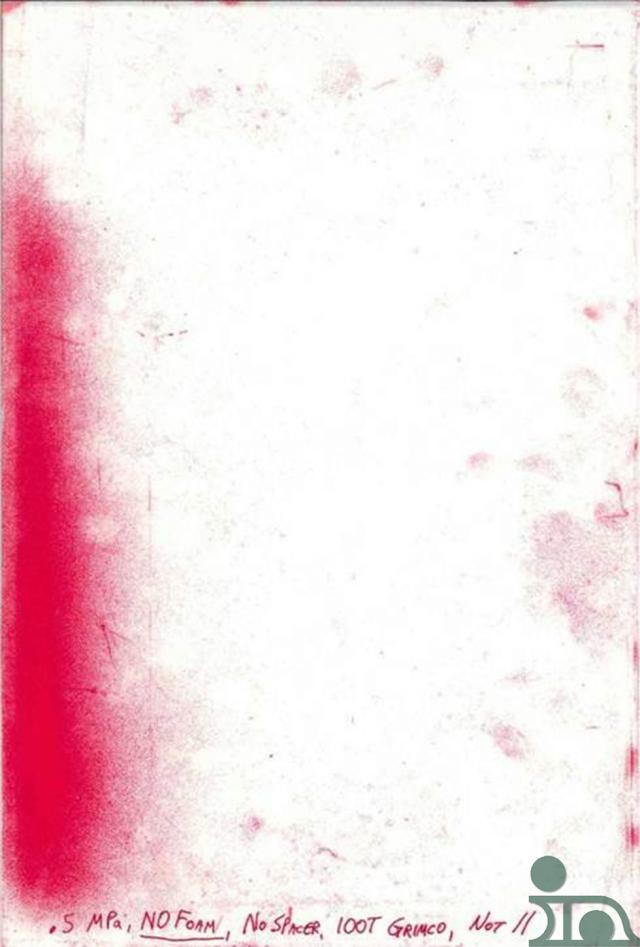

As illustrated in the pressure paper images below, uniform pressure across a NanoBond® interface is critical for maximum bond strength.

We will discuss this further in "Aligning the Assembly".

*This post is part of the NanoBond® Process series