When designing a Package-on-Package (PoP) assembly process, there are many variables that need to be considered in order to be successful. While the chemistry of your PoP dipping flux or paste plays a major role in PoP assembly, there is also much to consider in terms of the components, equipment, and reflow parameters being utilized.

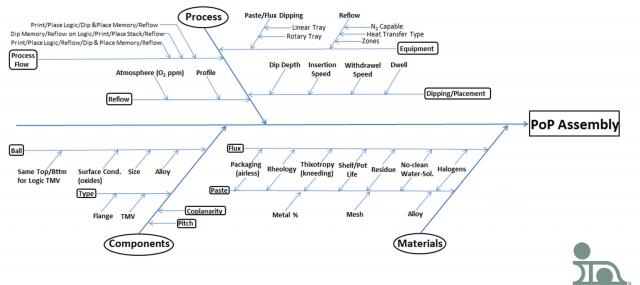

In order to help illustrate these variables, I have created the following Ishikawa diagram:

While I’m sure there are some variables that I have missed, these are the main ones to consider.

For help deciding which products are right for your PoP process or help troubleshooting your current process, please contact AskUs@indium.com.