Related Ball-Attach Blog Articles

Common Ball Grid Array Failures and How to Avoid Them

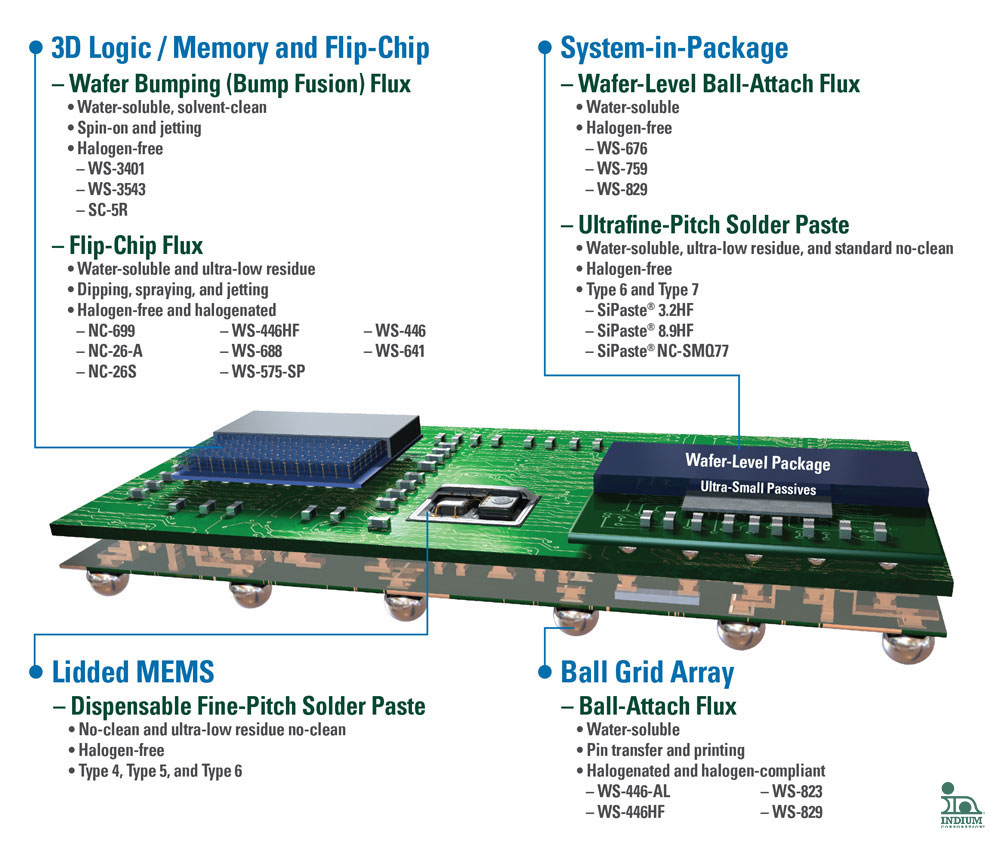

The BGA ball-mount process may seem uninteresting and trivial at first glance. However, the soldering steps are complex and can lead to problematic failures. Indium Corporation's ball-attach fluxes, such as WS-446HF, WS-823, and WS-829, were formulated to not only prevent these failures, but to eliminate some of the process steps which could cause these failures in the first place.

Read MoreBall-Attach Flux: WS-575-C-RT (VIDEO)

Currently, for the ball-attach process, customers are facing issues like warpage of the substrates...

Read MoreOne-Step OSP BGA Soldering Application

The ball-attach process can be considered a trivial step when creating an FCBGA or similar package, but the final soldering step can be rather complex. There are several variables that impact the final ball-attachment...

Read MoreTech Spotlight: Maria Durham

While not directly part of Indium Corporation’s Technical Service department, Maria is technology driven and works with our customers to help select the perfect products for their needs. In her role as Product Specialist...

Read MoreIMAPS 2013: International Symposium on Microelectronics

The 46th International Symposium on Microelectronics will be held in Orlando, Florida, September 30th through October 3rd, 2013. I will be attending both as as an exhibitor and as a session co-chair. TECHNICAL SESSION:...

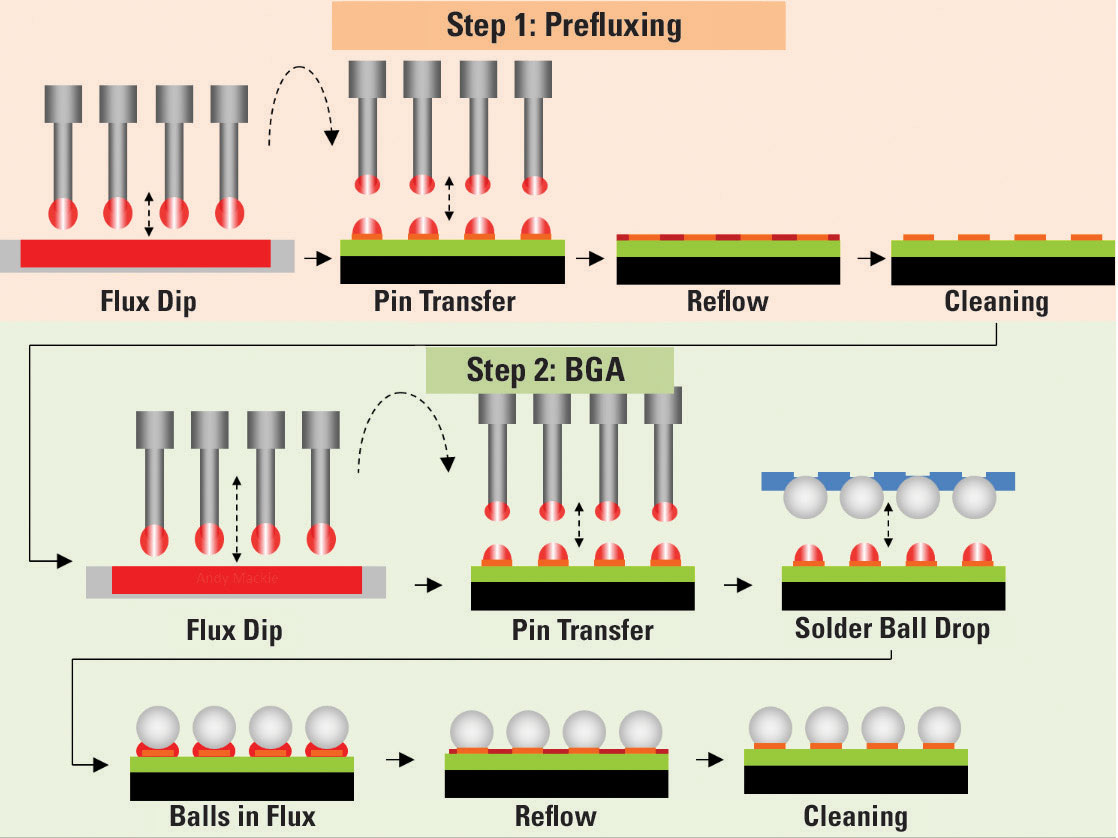

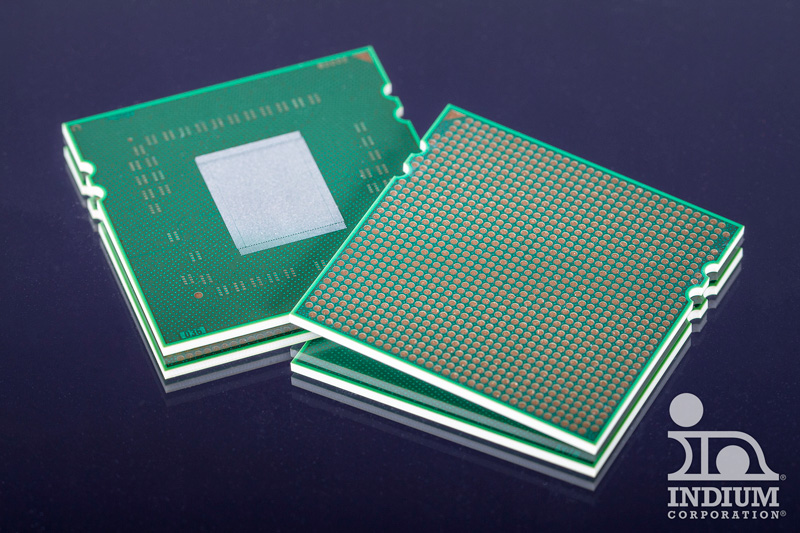

Read MoreThe ball-attach process can be considered a trivial step when creating a BGA or similar package, but the final soldering step can be rather complex.

There are several variables that impact the final ball-attach performance from a number of assembly processes carried out before that. These processes can be a key factor in the final yield of the BGA.

The ball-attach process for BGA and PGA packages uses a flux that is usually applied via pin-transfer from a dipping tray. Solder spheres (solder balls) are then placed into the deposits and the entire assembly is reflowed. BGA fluxes are usually water-soluble, while PGA fluxes are often no-clean materials.

Recommended Semiconductor Ball-Attach Fluxes

| Material Name | Flux Type | Halogen-Free | Application | Comments |

|---|---|---|---|---|

| WS-446-AL | Water-wash | No | Pin transfer | Best flux for poor solderability |

| WS-446HF | Water-wash | Yes | Pin transfer | Suitable for one-step Cu OSP process for sphere size 0.25mm and above |

| WS-823 | Water-wash | Yes | Pin transfer | Best all-around halogen-free ball-attach flux, easily cleaned |

| WS-829 | Water-wash | Yes | Printing and pin transfer | For sphere size <0.25mm and fine-pitch high-density ball-attach, best cleanability |

WS-446HF

WS-446HF Flux is a robust, halogen-free, water-wash flux that was designed to provide one simple solution to complicated applications, especially those with a single cleaning step for both BGA ball-attach and flip-chip processes. It has a powerful activator system to promote good wetting on even the most demanding substrate metalizations such as Cu OSP, ENEPIG, and ENIG. Its rheology is suitable for dipping flip-chip applications, as well as pin transfer or printing BGA ball-attach applications, for sphere sizes 0.25mm and above. WS-446HF helps to improve production yield by minimizing non-wet-open defects, missing balls, and electrochemical migration (ECM).

Features

- Good wetting, even on oxidized Cu OSP surfaces

- Consistent flux deposition with dipping, printing, and pin transfer applications

- High tackiness to hold die or spheres in place

- reduce die tilt

- reduce missing spheres

- reduce non-wet opens caused by warpage

- Eliminate dendrite issue

- Proven “one-step” process on Cu and Cu OSP surfaces

- Eliminate extra process costs

- Reduce package warpage

- Ease of cleaning

- Same flux for ball-attach and flip-chip, no cross-contamination

- Cleanable with room temperature DI water only

- No flux residue

- Low-voiding

- Halogen-free

WS-829

Ball-Attach Flux WS-829 is a halogen-free water-soluble ball-attach and LED die-attach flux designed for use in pin transfer and printing applications for ball-attachment to substrates (BGA manufacturing) and wafer/panel (WLP/PLP manufacturing). WS-829 can also be used for LED die-attach application. Its thixotropic property allows it to be printed on a substrate consistently with superb print definition for very small deposits without slumping. Its rheology is specifically designed for use with even the smallest gravity-fed spheres. WS-829 has an activator system powerful enough to promote wetting on the most demanding substrate metallizations. Flux residue of WS-829 can be effectively cleaned with just DI water without leaving any contamination behind.

Features

- Designed for ball-attach process, pin transfer, and printing applications

- Also suitable for miniLED or microLED die-attach application, printing through stencils with ultrafine apertures

- Halogen-free—per IPC and IEC specifications

- Flux rheology suitable even for smallest sphere size

- Thixotropic property ensures good print definition with minimal slump

- Promotes excellent solderability and wetting on a wide range of surfaces

- Good results on AuNi and even on oxidized Cu-OSP (up to 0.3mm-thick OSP)

- Promotes strong, low-voiding joints

- Cleans well with room temperature DI water

- Saves money on water heating

- No undesirable flux residue or contamination

- Designed for Pb-free applications

- Suitable for all high-tin solders

- Ensures consistent joint quality by providing consistent pin transfer and printing performance over extended periods

- Reduces “double ball” and “missing balls”

- Maintains tackiness during heating, results in minimal sphere movement

- Reflows in air or nitrogen

- Stable at room temperature for up to 6 months

WS-823

Indium Corporation’s Ball-Attach Flux WS-823 allows customers to use a halogen-free (NIA = no intentionally added halogens) single-step ball-attach process to eliminate the costly, wasteful, and warpage-inducing effects of prefluxing. The “Standard Ball-Attach Process” is the typical two-step flux processing that is needed to create reliable, ball-to-pad joints from final BGA balling, especially on Cu pads. The prefluxing step can only be eliminated if the flux has sufficient activity to overcome the extent of the oxidation on copper and create strong solder joints. WS-823 is customer-proven to be able to eliminate the need for multiple fluxing steps before final ball-attach.

Features

- Halogen-free – no intentionally added (NIA) halogens

- Eliminates process costs and warpage due to prefluxing

- No extra fluxing, reflow, cleaning, and substrate warpage

- Reflows in air or nitrogen

- Can eliminate the cost of nitrogen

- No missing ball defect

- Tack during heating and fast soldering ensures balls stay in place during reflow

- Excellent solderability on a wide range of surfaces

- Good results on AuNi and even on oxidized Cu OSP (up to 0.3mm-thick OSP)

- Uniform pin transfer over extended periods

- Avoids changes of joint quality over time and uneven deposit sizes, which can lead to missing balls

- Low-voiding

- Increases joint strength

- Designed for Pb-free applications

- Suitable for all high-tin solders: SAC105, SAC305, SAC385, SAC405

- Cleanable with room temperature DI water only

- Saves money on water heating

- No “white residue”

- Cleaning the flux residues at lower temperatures avoids the formation of white residues

- Stable at room temperature

- Ease of storage and use without crystals or gel balls

- Ready to use, straight from the jar or cartridge

WS-446-AL

Ball-Attach Flux WS-446-AL is a thixotropic flux designed for use in pin transfer applications for ball-attachment to substrates (BGA manufacturing). Its rheology is specifically designed for use with even the smallest gravity-fed spheres. WS-446-AL’s halogen-containing activator system is powerful enough to promote wetting on the most demanding substrate metallizations. The flux is a distinctive red color, which aids automated level-sensing equipment and also enhances visual inspection.

Features

- Flux rheology applicable for all sphere sizes

- Suitable for Pb-free or SnPb applications

- Uniform pin transfer over extended periods

- Red color for ease of detection

- Proven high yields in ball-attach process

- Excellent solderability on a wide range of surfaces

Proven “One-step” Process on Cu and Cu OSP Surfaces

True one-step process where prefluxing step is no longer needed.

| Flux Type | BM Step | Shear Strength | Average Void % | Max Void % |

|---|---|---|---|---|

| Competition | Preclean + BM | Pass | 5.6% | 3.0% |

| WS-446HF | One-step BM | Pass | 4.4% | 2.3% |