PCB Assembly Solder Pastes

Lead-Free Solder Pastes

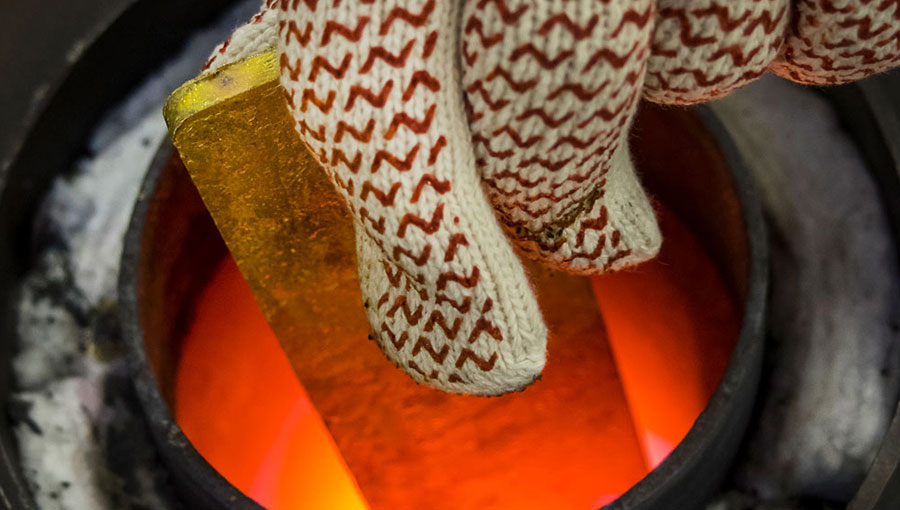

As a lead-free leader in the electronics assembly industry, Indium Corporation offers a wide range of Pb-free solder pastes, including no-clean, water-soluble, and RMA. Designed to meet the rigorous demands of modern electronics manufacturing and environmental regulations, our lead-free solder pastes deliver uncompromised performance and reliability.

Powered by Indium Corporation

- Lead-Free

- Proven High-Performance

- High Quality

Product Overview

Widely Compatible

The majority of our flux vehicles are compatible with Pb-free alloys and other products, such as cored wire and solder bars.

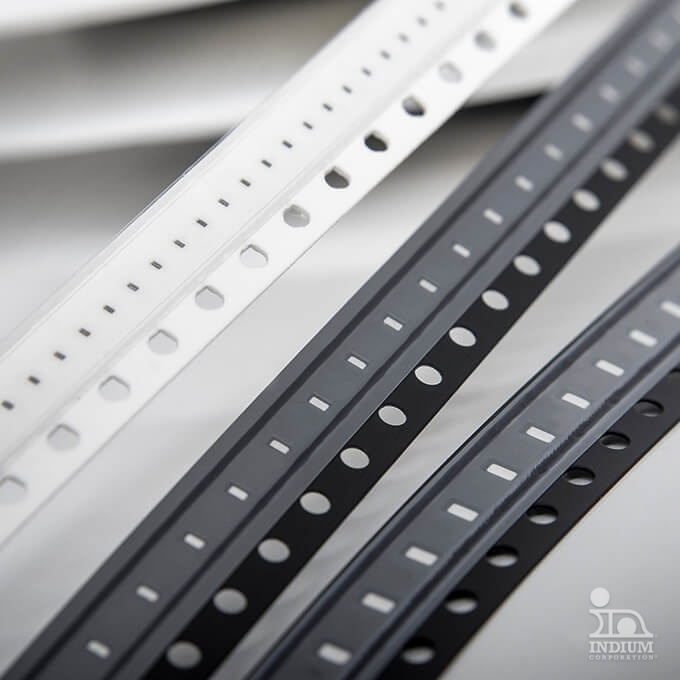

Wide Selection

Indium Corporation offers various lead-free solder pastes for circuit board assembly, including Durafuse® Technology for low-temperature soldering and high reliability.

Proven

With decades of proven flux technology, our lead-free solder pastes provide customers with the highest end-of-line yields.

Versatile

We offer many different alloy choices and flux technologies to solve many of your process challenges.

Lead-Free Solder Paste Products

Indium 8.9HF Series Products

The Indium8.9HF Series offers a range of formulas tailored to meet diverse application needs and tackle various challenges. It is compatible with both Pb-free and Pb-containing alloys, ensuring versatility across different soldering processes.

Indium8.9HF

Best all-around halogen-free paste

Indium8.9HFRV

High TCT performance, low voiding, no-clean paste

Indium8.9HF1

To pair with our high-reliability alloys. Enables in-circuit probe testing

Indium8.9HFA

Superior printing for miniaturization

Indium8.9HFT

Next generation best-all-around halogen-free paste

Indium10 Products

Indium10 provides a selection of formulas specifically designed to address a variety of application needs and challenges. Compatible with both Pb-free and Pb-containing alloys, it guarantees versatility in the soldering process.

Indium10.8HF Series

Addresses non-wet opens (NWOs)

Indium10.1HF

Ultra-low voiding in air reflow

Indium10.2HFA

Unprecedented stencil print transfer efficiency

Indium10.1

Best all-around halogen-containing solder paste

Product Data Sheets

NC-SMQ230 Pb-Free Solder Paste PDS 97722 R18.pdf

NC-SMQ230 Pb-Free Solder Paste PDS 97722 (A4) R18.pdf

Indium8.9HFRV Pb-Free Solder Paste PDS 100328 R1.pdf

Indium8.9HFRV Pb-Free Solder Paste PDS 100328 (A4) R1.pdf

Related Applications

Indium Corporation’s Lead-Free Solder Pastes are engineered to meet the demanding standards of modern electronics manufacturing.

Related Markets

Indium Corporation’s lead-free solder pastes are widely used in industries from consumer electronics to aerospace and military.

Expert Support for Reliable Results

Do you have technical questions or sales inquiries? Our dedicated team is here to help. “From One Engineer to Another®” isn’t just our motto—it’s our commitment to delivering exceptional service. We’re ready when you are. Let’s connect!

Looking for Safety Data Sheets?

Access everything you need — from technical specifications to application guidance — in one convenient location.

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.