Related Robotic Soldering Blog Articles

Golf and Robotic Soldering: Another Unique Comparison

The Masters Tournament is right around the corner. It got me to thinking, "How are golf and robotic soldering alike?" In this short blog, I cover exactly that.

Read MoreRevolutionizing Electronics Assembly: The Future of Robotic Soldering

Explore the growing importance of robotic soldering in electronics assembly, addressing challenges such as miniaturization and cycle time demands. Discover how advanced soldering materials and AI innovations can enhance efficiency and consistency, shaping the future of the industry.

Read MoreA Proper Solder Introduction Point in Hand or Robotic Soldering Can Solve Many Common Issues

The introduction point between the pad and the soldeirng iron tip plays a crucial role in creating perfect solder joints, as well as gives clues as to why soldering has gone awry when improper technique is use.

Read MoreAutomated Soldering Methods: What’s the Difference Between Robotic Soldering and Laser Soldering?

Laser soldering is making its way into the market and onto electronics assembly lines. What's the difference between this method and iron-tip robotic soldering? Read to find out.

Read MoreWhat Do the Equipment Suppliers Have to Say?

In this blog post, I share the reactions of soldering iron tip equipment suppliers to the statement: “As temperature increases, tip life decreases.”

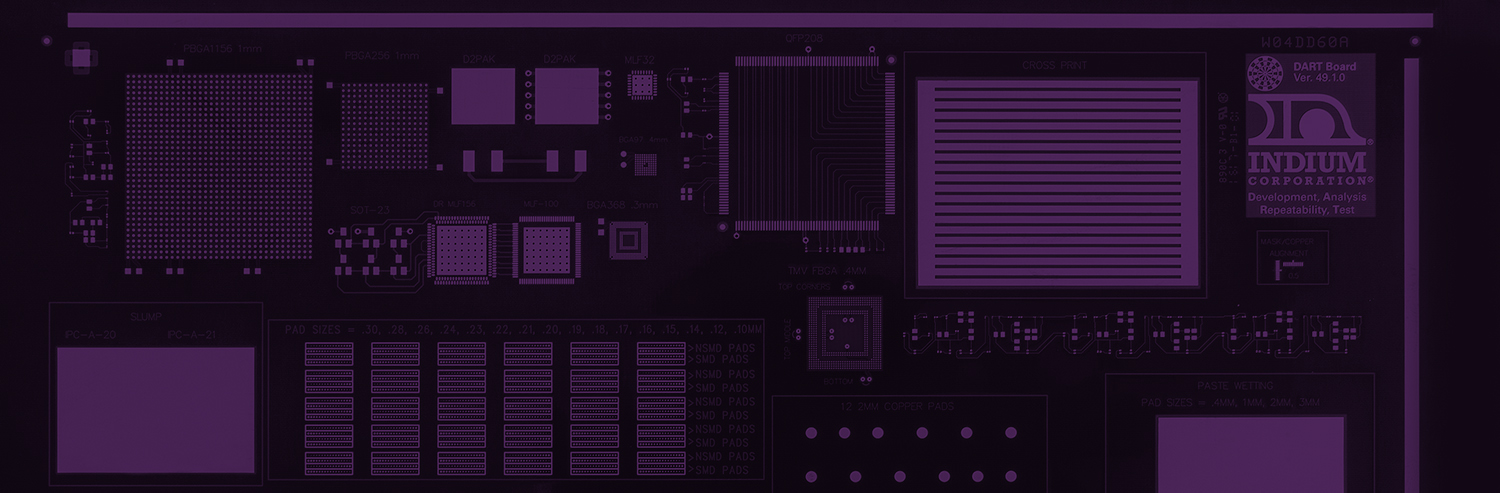

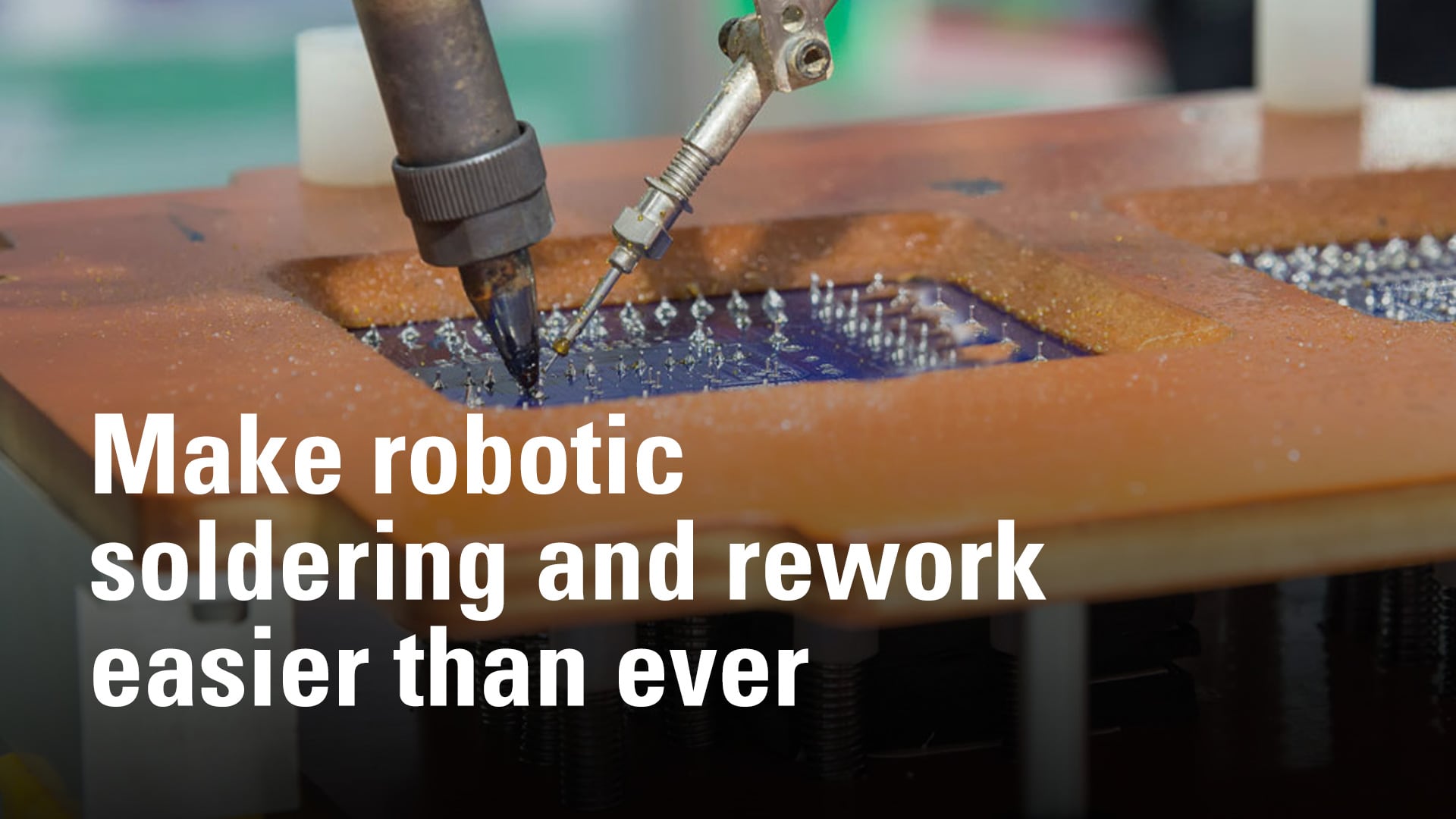

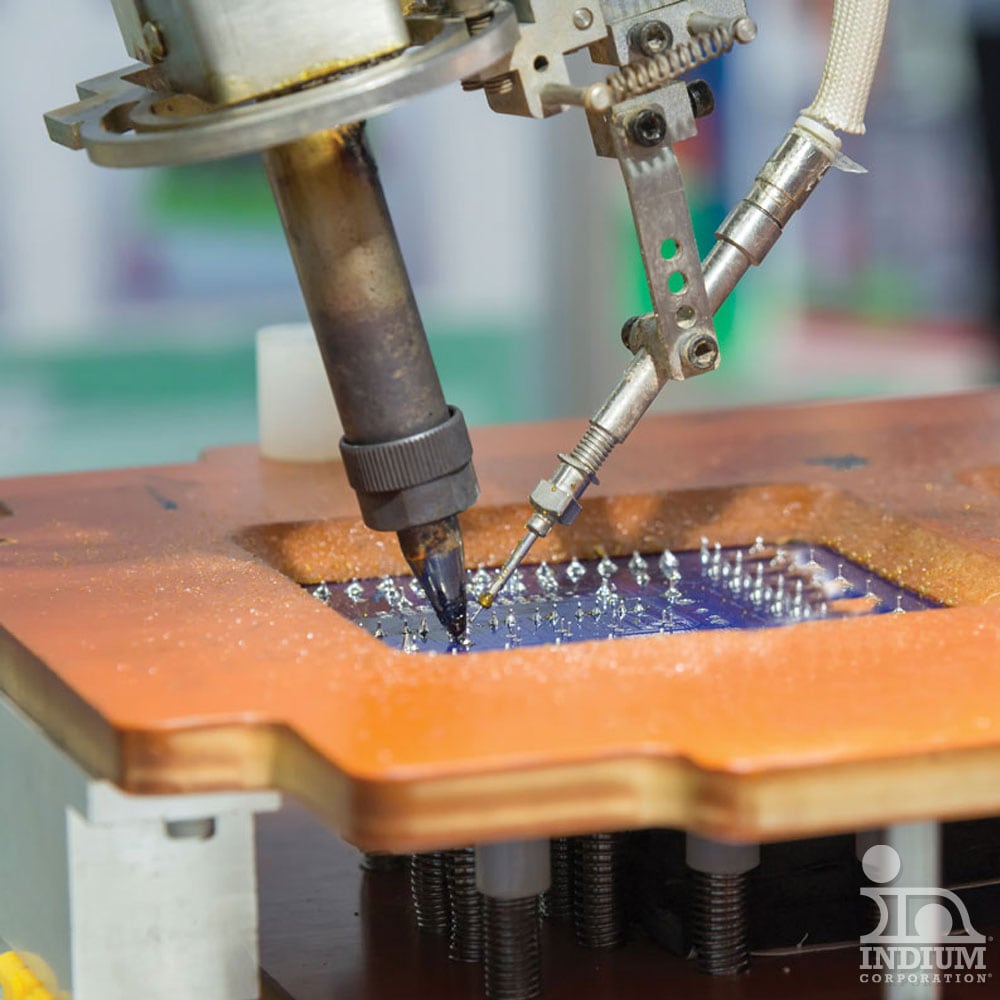

Read MoreIndium Corporation manufactures flux-cored solder wire for a variety of processes, including automated or robotic soldering for large job lots, or jobs where other processes are not feasible. By providing reliable, high-quality robotic soldering materials, coupled with our world-class soldering expertise and knowledge, we can improve your processes and yields.

Our flux-cored soldering wire manufacturing capabilities gives you void-free wire that is consistent in diameter and wound in highly precise even layers throughout the spool. Flux-cored wire can contain a range of flux core sizes, from 1% up to 4.5% or more. By optimizing the core size, it facilitates the soldering process and eliminates the need for a separate flux, streamlining automated processes.

Excellent Quality on Every Spool of Wire

- Void-free flux core

- Even-layer precision winding

- Fluxes achieve highest activity acceptable given reliability concerns (J-STD-004B)

- All alloys comply with J-STD-006

Available Features

- No-spattering for improved yields and enhanced cleanliness

- REACH Compliance

- Turbo-charged wetting

- Halogen free

CW-818 Flux-Cored Wire

CW-818 provides fast wetting speeds to minimize cycle times in manual and robotic soldering processes. This halide-free, no-clean formula leaves a clear, non-tacky residue even when using high tip temperatures. The heat resistant and low-spatter properties of this core flux provide an assembly with excellent visual appearance.

- Features

- Fast wetting

- Light-colored non-tacky residue

- Reduced spatter formulation

- Works well for manual and robotic soldering processes

- Compatible with Pb-free and SnPb alloys

- Compatible with HASL, Immersion Silver, ENIG, and OSP surface finishes

- Good choice for legacy processes requiring an RMA strength product

Core 230-RC Flux-Cored Wire

- Physical Properties

- Meets the requirement of J-STD-004B Type REL1

- Low-spatter formation gives you cleaner boards and increased operator safety with less than 1% spattering

- Light-colored residue

- Contains no REACH SVHCs

- Compatible with Pb-free and SnPb alloys

- Compatible with HASL, Immersion Silver, ENIG, and OSP surface finishes

- Available in flux percentages up to 4.5%

- No residue removal required

- Very high surface insulation resistance (SIR)

CW-232 Flux-Cored Wire

- Physical Properties

- Meets the requirement of J-STD-004B Type ROM1

- Low-spatter formation gives you cleaner boards and increased operator safety with less than 1% spattering

- Light-colored residue

- Contains no REACH SVHCs

- Compatible with Pb-free and SnPb alloys

- Compatible with HASL, Immersion Silver, ENIG, and OSP surface finishes

- Available in flux percentages up to 4.5%

- No residue removal required

- Very high surface insulation resistance (SIR)

CW-808 Flux-Cored Wire

- Physical Properties

- Meets the requirement of J-STD-004B Type ROL0

- Low-spatter formation gives you cleaner boards and increased operator safety with less than 1% spattering

- Available in flux percentages up to 4.5%

- No residue removal required

- Contains no REACH SVHCs

- Very high surface insulation resistance (SIR) (greater than the control)

Cored Wire and Robotic Soldering

| Formula | J-STD-004B/C | Halogen-Free | Spatter | Soldering Performance |

|---|---|---|---|---|

| CW-818 | ROL0 | No | Low | Fastest |

| CW-232 | ROM1 | No | Lowest | Fastest |

| Core 230-RC | REL1 | No | Lowest | Fast |

| CW-808 | REL0 | Yes | Lowest | Moderate |

Robotic Soldering Application Knowledge

Indium Corporation has written about and published papers on the topic of Robotic Soldering. This includes technical documents and blogs. Topics covered include:

- Spattering:

- Flux Charring:

- Soldering Iron Tip Temperature:

- Wire Voiding:

- Wire Tension:

We have also produced multiple videos on the topic of Robotic Soldering.