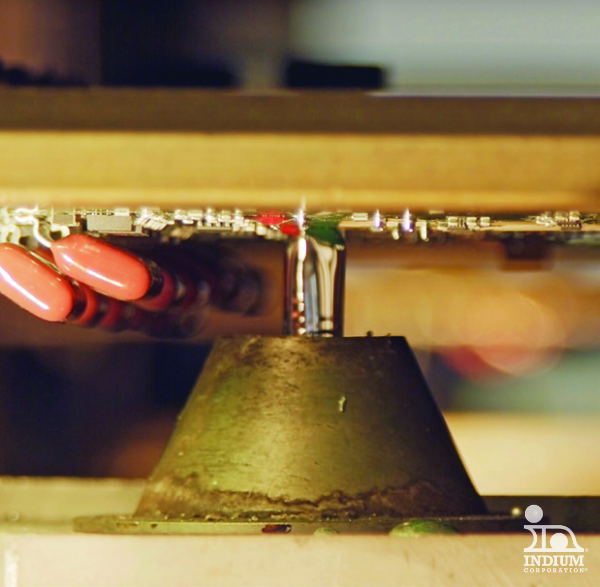

Selective Soldering is a method of soldering components to a printed circuit board in a way that is faster than hand soldering and consumes less solder than traditional wave soldering. It is becoming known within the industry as one of the most effective soldering methods available, and its usage continues to increase as assemblers transition away from other costlier soldering methods. Indium Corporation manufactures a number of products well-suited for selective soldering applications, such as WF-9945, WF-9948, and WF-9958.

Benefits of Selective Soldering

- Cost optimization

- Process flexibility

- Quick and easy process optimization

- Creation of reliable solder joints without overheating nearby components

- Process repeatability

- No need for costly aperture wave solder pallets

- No need for gluing components in place

- Different components can receive different soldering parameters during the same run

No-Clean Rosin-Containing Fluxes

Fluxes that have high solids content, as well as higher amounts of halogen, tend to be more heat-stable and solder better with a variety of board types, sizes, and thicknesses. Fluxes with lower solids contents and no rosin tend to be easier to electronically probe-test and have less visually apparent residue. Halogen content is not necessarily an indicator of final circuit board reliability since halogen types vary and rosin in the flux will enhance an assembly’s surface insulation resistance.

No-Clean Rosin-Containing Flux Products

WF-9948

Indium Corporation's Lead Selective Soldering Product

WF-9948 is a fourth-generation high-performance no-clean wave solder flux designed for use with through-hole and mixed-technology assemblies. While only containing about 3.3% flux solids, WF-9948 is very heat stable and well-suited for selective soldering applications. It performs well with both tin-lead and lead-free solders. It has been designed to pass all known reliability requirements, including J-STD-004B SIR and ECM. This modern flux is non-corrosive and compatible with most conformal coatings. It is also compatible with probe testing and does not contribute to detrimental circuit board insulation resistance degradation or electrochemical migration.

WF-9945

WF-9945 is a halogen-free no-clean flux developed for wave soldering mixed-technology and through-hole electronics assemblies. The rosin increases heat stability and widens the effective heat profiles, allowing for very high yield when wave soldering larger, thicker, and more complex circuit boards. WF-9945 is designed for use with tin-copper, tin-silver-copper, and tin-lead alloys.

3545

No-Clean Rosin-Free Fluxes

Fluxes that have high solids content, as well as higher amounts of halogen, tend to be more heat-stable and solder better with a variety of board types, sizes, and thicknesses. Fluxes with lower solids contents and no rosin tend to be easier to electronically probe-test and have less visually apparent residue. Halogen content is not necessarily an indicator of final circuit board reliability since halogen types vary and rosin in the flux will enhance an assembly’s surface insulation resistance.

No-Clean Rosin Flux Products

WF-9958

WF-9958 has no intentionally added halogens, no rosin, and exhibits exceptional hole fill as well as pin-testing performance that can only be achieved with a rosin-free material. WF-9958 is designed to conform to the more rigorous standards of J-STD-004B Type ORM0.

Water-Soluble Fluxes

Before no-clean fluxes became the most commonly used materials in wave soldering, water wash fluxes had an extended run as the preferred material. The advantage of water wash fluxes is that they can be formulated to be very active so that they can solder virtually any assembly without a concern for reliability, since the residue will be removed after the soldering process. The disadvantage of water wash fluxes is that assemblers must have an additional piece of equipment, the water wash system, to remove the flux residue, and must deal with the effluent.

Neutral pH fluxes, such as WF-1098, can generally be left on the circuit board for extended periods of time before washing, while the “low” pH fluxes generally solder somewhat better.

Water-Soluble Flux Products

WF-1082

WF-1082 is an alcohol-based, halogen-free, water-wash wave solder flux developed to comply with the latest J-STD-004, version B, and for soldering through-hole, bottom-side surface mount, and mixed-technology circuit boards. It performs well with both Pb-free and SnPb solders and processes and is compatible in both wave soldering and selective soldering applications.

WF-1098

WF-1098 is an alcohol-based, halogen-containing, water-wash wave solder flux developed to comply with the latest J-STD-004, version B, and for soldering through-hole, bottom-side surface mount, and mixed-technology circuit boards. It performs well with both Pb-free and SnPb solders and processes and is compatible in both wave soldering and selective soldering applications. WF-1098 is a neutral pH flux. The halogens give the flux additional activity and heat stability.

VOC-Free Fluxes

VOC-free fluxes use water as the dominant solvent. In addition to limiting the amount of volatile organic compounds (VOC) into the atmosphere, VOC-free fluxes are also non-flammable. The disadvantage of VOC-free/water-based fluxes is that they require more pre-heat to drive off the water than alcohol-based fluxes. In addition, assemblers must be careful to ensure that the top side of the circuit board is dry, otherwise it could lead to reliability issues in the form of electromigration.

VOC-Free Flux Products

WF-7745

WF-7745 is a water-based, VOC-free, halogen-free, no-clean wave solder flux designed for wave soldering through-hole, bottom-side surface mount and mixed technology circuit boards. It performs well with both Pb-free and SnPb solders and processes. WF-7745 is non-flammable, dramatically reducing volatile organic compound emissions and eliminating special flammable storage conditions.