Applications

Substrate / Spacer-Attach

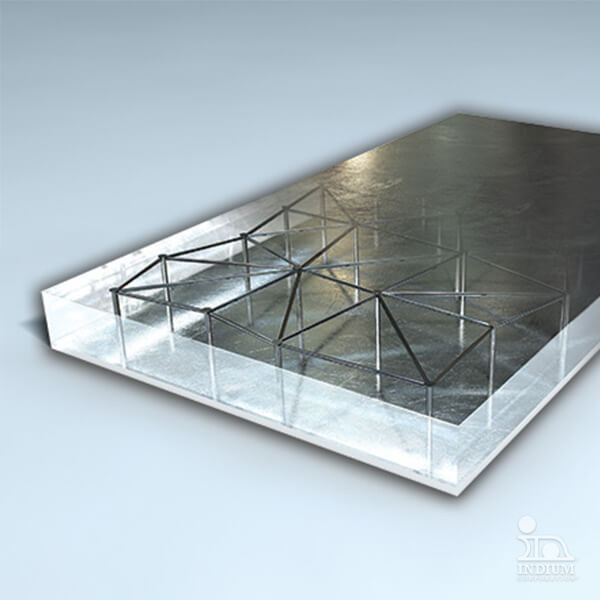

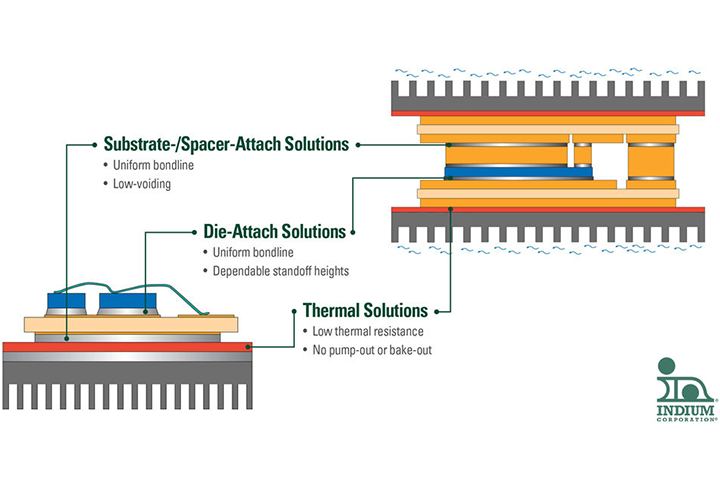

In power module assemblies, the substrate serves as the thermomechanical foundation, supporting active devices and interconnects. Traditionally, the substrate is attached to a baseplate. However, alternative methods, such as Dual-Side Cooling, use a spacer to provide both mechanical support and efficient heat dissipation. Both approaches face challenges such as thermal and mechanical stress, warpage, and CTE mismatch, making the choice of reliable substrate-attach materials critical.

Overview

Proven Materials Technologies to Achieve Design Goals

Indium Corporation’s solder performs feature a range of proven technologies, including InFORMS® reinforced preforms and the highly reliable Indalloy® 276. These materials are recognized as the premier substrate-attach solutions, widely utilized throughout the power module industry.

Benefits

Indium Corporation’s Substrate-Attach Materials Offer the following:

Semiconductor assembly involves the process of packaging and interconnecting semiconductor chips or integrated circuits, onto a substrate to create functional electronic devices.

Extended Device Life

Precision Design Control

Low Temperature Options

Seamless Integration

Ease of Use

Related Applications

Related Markets

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.