Products

Innovative Materials.

Global Solutions.

As a global leader in advanced materials, Indium Corporation delivers innovative products, including solders, sinter pastes, thermal interface materials, tacky agents, and metals such as indium, gallium, germanium, and tin. Our solutions power industries worldwide, while our trusted reclaiming and recycling services deliver sustainable support along the way.

-

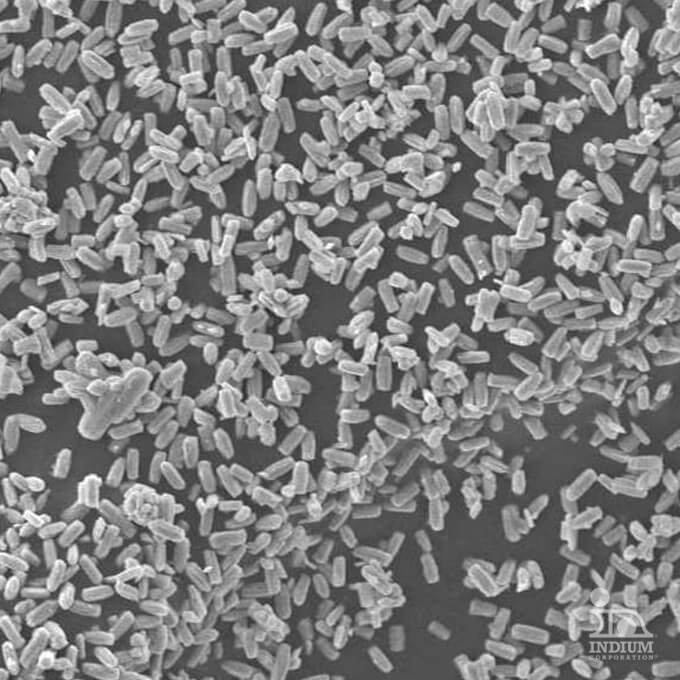

Formic Acid Soldering Technologies (FAST)

A patented solder alloy technology to enable…

-

Gallium Compounds

High-quality products like gallium tri-chloride and gallium…

-

Gallium Oxide

High-quality product used in power electronics &…

-

Gallium Trichloride (EZ-Pour®)

Exclusive high-purity and safer EZ-Pour® Gallium Trichloride.

-

Gallium Acetylacetonate

A key precursor for many applications, such…

-

Germanium Compounds

High-purity germanium oxide and germanium tetrachloride.

-

Germanium Oxide

A versatile compound for optics, catalysis, and…

-

Germanium Chloride

High-Purity Germanium Chloride for Optics and Semiconductors.

-

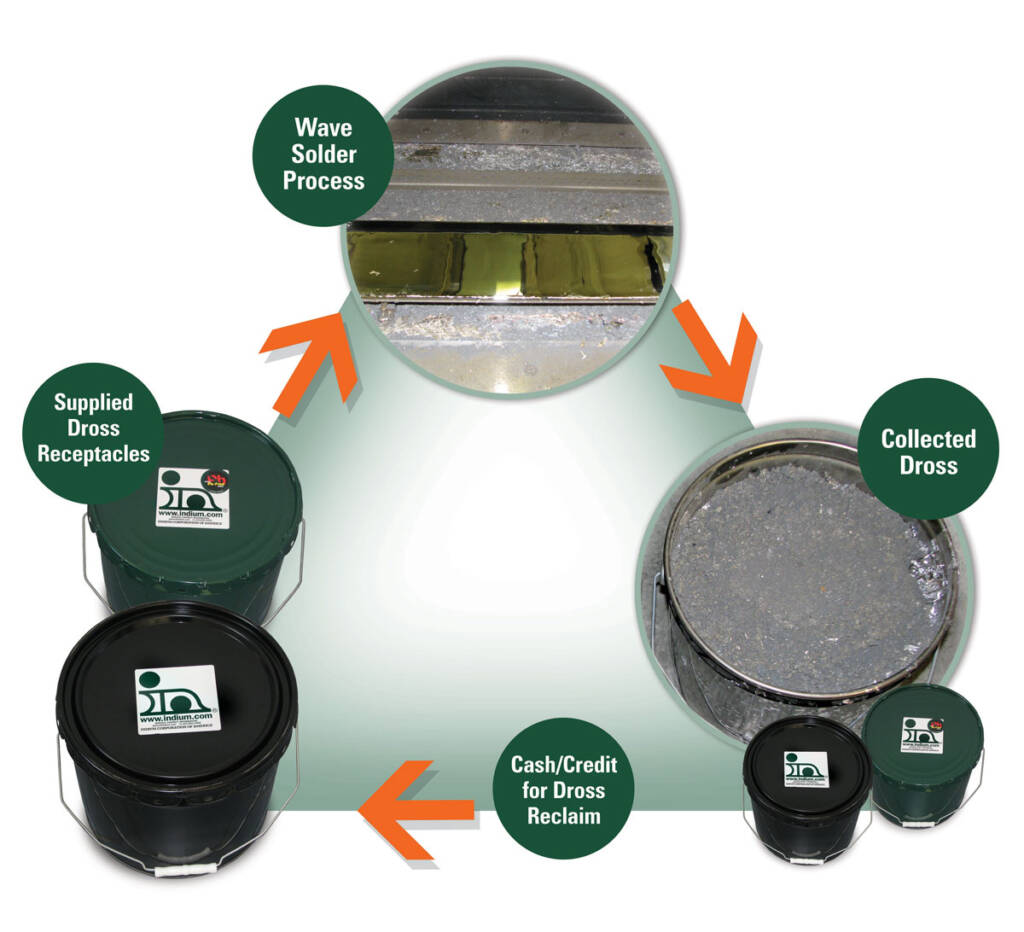

Reclaim and Recycle

Reclaim and recycle service for metals, solder,…

-

Solder Dross

Discover a cost-effective and safe way to…

-

Avoid the Void®

Featuring advanced solder technology to minimize voiding.

-

Durafuse® Technology

A patented solder alloy technology to enable…

-

Fusible Alloys/Low Melting Point Alloys

Utilize low melting points for easy attachment.

-

Liquid Alloys

Explore versatile liquid alloys with low melting…

-

Indalloy®301LT

Indalloy® 301LT offers versatile solder forms &…

-

Indalloy®276

Pb-free solder offering high reliability up to…

-

Durafuse® LT

Patented low-temperature mixed alloy system for high…

-

Durafuse® HR

High-reliability & low-voiding Solder Alloy Durafuse® HR.

-

Durafuse® HT

High-temperature Pb-free solder paste alloy Durafuse® HT.

-

Compounds

High-purity indium, gallium, and germanium compounds.

-

Indium Compounds

High-purity indium compounds for diverse industry applications.

-

Indium Acetate

A key ingredient in quantum dot production,…

-

Indium Trichloride (IndiTri®)

Powder and solution forms to meet various…

-

Indium Hydroxide

A vital precursor for crafting indium-based materials.

-

Indium Nitrate

High purity & stability, used in chemical…

-

Indium Oxide (IndiOx®)

High-purity compound for advanced technologies.

-

Indium Tin Oxide (ITO)

Top-notch, high-purity ITO products in large quantities.

-

Indium Sulfate

Versatile for electroplating and gold baths

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.