Applications

Die-Attach

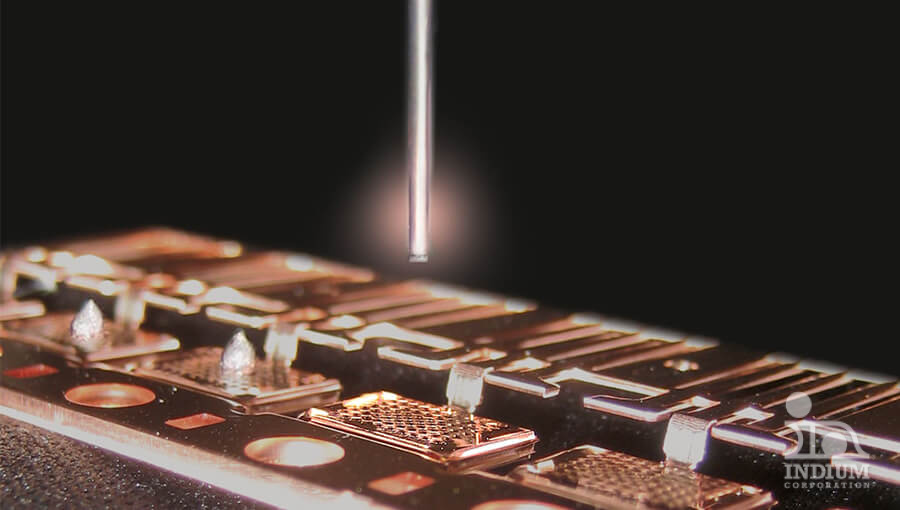

Die-attach involves securing semiconductor dies—typically Si, SiC, GaAs, or GaN—to a lead frame or substrate. This step is essential in establishing a mechanically reliable interconnection while also ensuring that the thermal and electrical properties meet the application’s requirements. Required levels of reliability, thermal conductivity, and electrical conductivity vary across applications, highlighting the importance of selecting the most suitable die-attach material. As a trusted partner in optimizing existing processes and developing innovative solutions, Indium Corporation offers a wide range of die-attach solutions from solder paste, to specialty preforms, to sinter materials.

Overview

Revolutionizing Semiconductor Die-Attach Materials for High-Power Devices

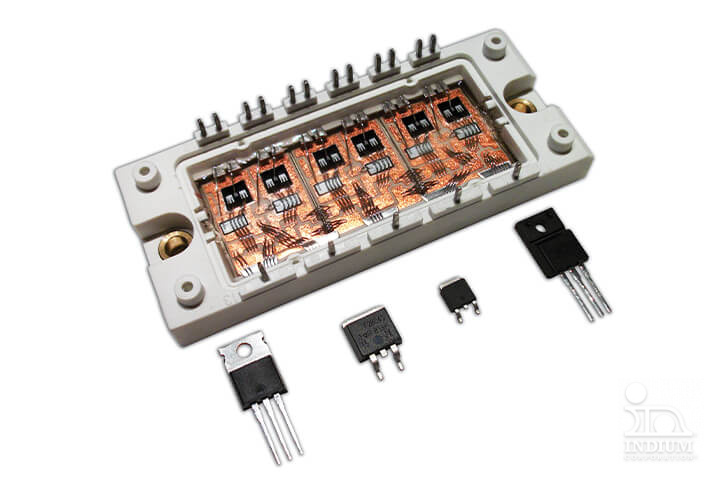

Die-attach for high-power devices, such as IGBTs and emerging wide bandgap semiconductors, face increasing challenges related to service temperature, power density, and reliability. Traditional high-lead solder materials are reaching their performance limits, but we have developed—and continue to innovate— advanced lead-free semiconductor die-attach materials to overcome current and future challenges.

Benefits

High Reliability, Thermal Conductivity, and Electrical Conductivity Across Various Applications

Low Voiding

Our die-attach solutions offer exceptional performance in reducing voids, guaranteeing optimal thermal performance for the application.

High-Reliability Alloys

We offer a wide range of dependable alloys for solder pastes and preforms that meet or surpass industry standards.

Customization

We work closely with our customers and partners to provide tailored soldering solutions for die-attach applications that meet their specific requirements.

Technical Expertise

With profound knowledge and extensive experience in die attach and related materials, our global team of technical experts is ready to offer valuable guidance and support for your project.

Choose the Right Materials for Die-Attach Semiconductor Applications

You can choose from a variety of materials for die-attach processes, including high-temperature solder pastes and gold-based solders. Each option offers distinct advantages and trade-offs, requiring careful evaluation based on the specific application requirements. We offer a range of proven products and solutions to help our customers make the best choice for their needs.

Related Applications

Related Markets

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.