Applications

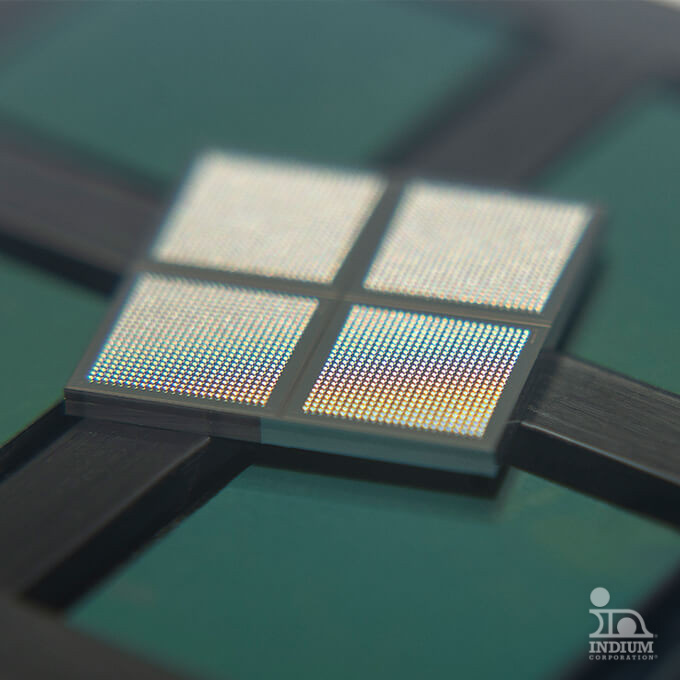

System-in-Package (SiP) and Heterogeneous Integration Assembly (HIA)

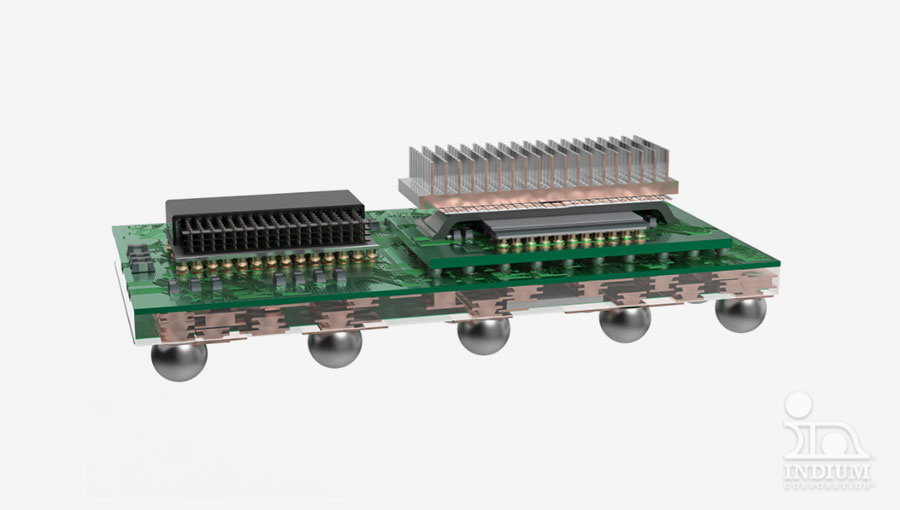

Advanced semiconductor technology, including system-in-package (SiP) and heterogeneous integration, involves combining various semiconductor devices into a single package to improve functionality, performance, and reduce form factor—while remaining cost-effective. SiP, a form of heterogeneous integration, enables the development of complex systems for high-performance devices. At Indium Corporation, our deep understanding of technology and processes allows us to create high-quality soldering products, including SiP solder paste, semiconductor fluxes, and high-performance thermal interface materials. These innovations ensure reliable electrical, mechanical, and thermal connections within integrated systems.

Overview

Proven Solutions to Solve Current and Future HIA Challenges

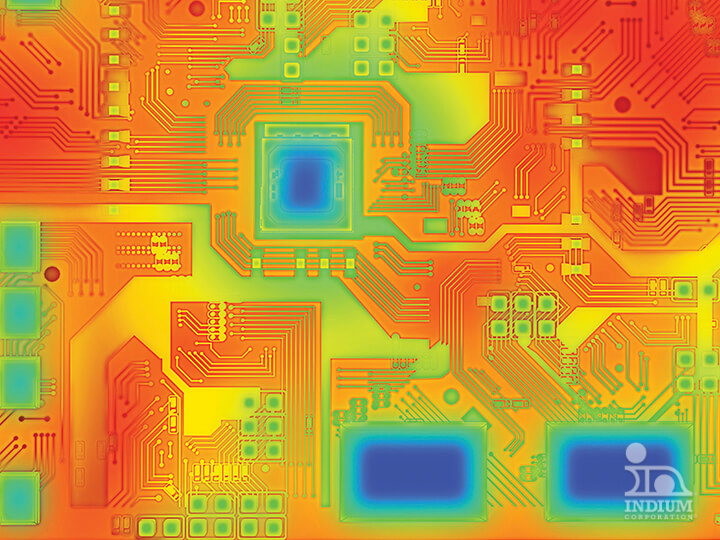

Miniaturization and the demand for enhanced functionality are making HIA and SIP more popular, driving the need for further development of these technologies. These growing needs present challenges for OSATs in package design, requiring high-performance thermal management materials and designs for more efficient heat dissipation, as well as true no-clean fluxes and fine powder solder pastes due to shrinking standoffs.

Benefits

Soldering Solutions for SIP and HIA Assembly Challenges

Proven Performance

Our products have been integral in the advancement of semiconductor assembly. Specifically, the wafer bumping flux WS-3401 and flip-chip flux WS-641 are used in high-volume manufacturing for 2.5D applications.

First No-Clean

Indium Corporation introduced the first ultra-low residue flux over a decade ago and has remained a pioneer, offering a diverse range of these advanced fluxes.

Preferred SiPastes

For over 5 years, SiPaste® 3.2HF has been the top choice for millions of manufacturers modules, with use in more than 5 billion front-end SiP modules to date.

Sustainability

Indium Corporation’s advanced fluxes enable a true no-cleaning process, supporting sustainability by cutting costs tied to cleaning chemicals, water, and energy usage.

Extensive Range of Thermal Solutions

Indium Corporation offer a wide variety of thermal solutions, from solder TIMs to liquid metals and liquid metal paste. These offerings cover a wide range of thermal conductivity, choices of TIMs for different applications are available.

Complete Portfolio

From easily cleanable water-wash solutions with DI water to true no-clean options, and from soldering solutions to thermal interface materials, we provide comprehensive solutions that help our customers solve problems and drive new designs and development.

Thermal Management (TIMs)

System-in-Package

3D Logic / Memory & Flip-Chip

Ball Grid Array

SMT

Related Applications

Related Markets

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.