Related Thermal Evaporation Blog Articles

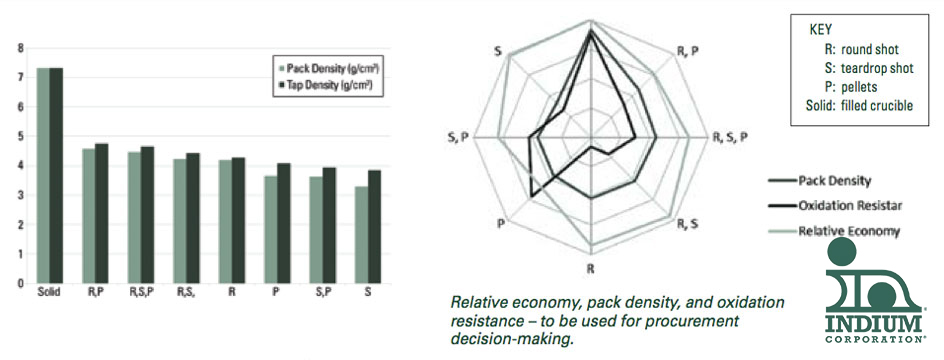

Thin Film Technology: Maximize Evaporation Crucible Packing Density

With a set crucible volume, and run times limited by the amount of evaporation material in the crucible, the density of the material in the crucible becomes important. Any loose form of material will...

Read MoreIndium Sulfide for Thin Film Solar Cells

Here’s an interesting technology fact I just learned: Indium Sulfide was the very first indium compound to be discovered. I bet Reich and Richter (the discovers of indium) never imagined that smelly little compound would be used build solar modules and provide electricity. img alt="" src="//cdn2.content.compendiumblog.com/uploads/user/af12973f-cd7e-4c45-9491-c37a7fb2af13/f257d3c4-c185-4407-a4e9-16920aaabcb7/Image/632527810d9659bfd85c7155f6fa9776/cigs_sem_cross_section.jpg" style="border-width: 5px; border-style:...

Read MoreThe Future of Solar Module Assembly: An Interview with Indium's Jon Major

Jon major recently joined the Indium Corporation as a Product Manager for Solar back-end assembly products. I greeted him with this impromptu interview. img height="400" width="300" align="right" src="http://cdn.content.compendiumblog.com/uploads/user/af12973f-cd7e-4c45-9491-c37a7fb2af13/c88ecbdf-a15d-4606-a0d8-7190af1ff183/Image/aa64fcc163af9d9405b99334cf3fc732/jon_major_2_w640.jpeg" alt="Indium Corporation's Jon Major." title="Indium Corporation's Jon Major." style="border: medium...

Read MoreMixing Low-Temperature Metallization Paste

Yesterday was a pretty interesting day. I happened to stop by the lab, and I had a chance to help mix silver into what will soon be the newest low-temperature metallization paste for the solar industry! It was an experience that...

Read MoreDr. Alan Rae: Nanotechnology in Electronics Assembly

I caught up with Alan Rae after a recent IWLPC committee meeting, where he jokingly asked me to, “Stop asking important questions” – LOL! He was kind enough to give me a few moments of his time to share his wit and...

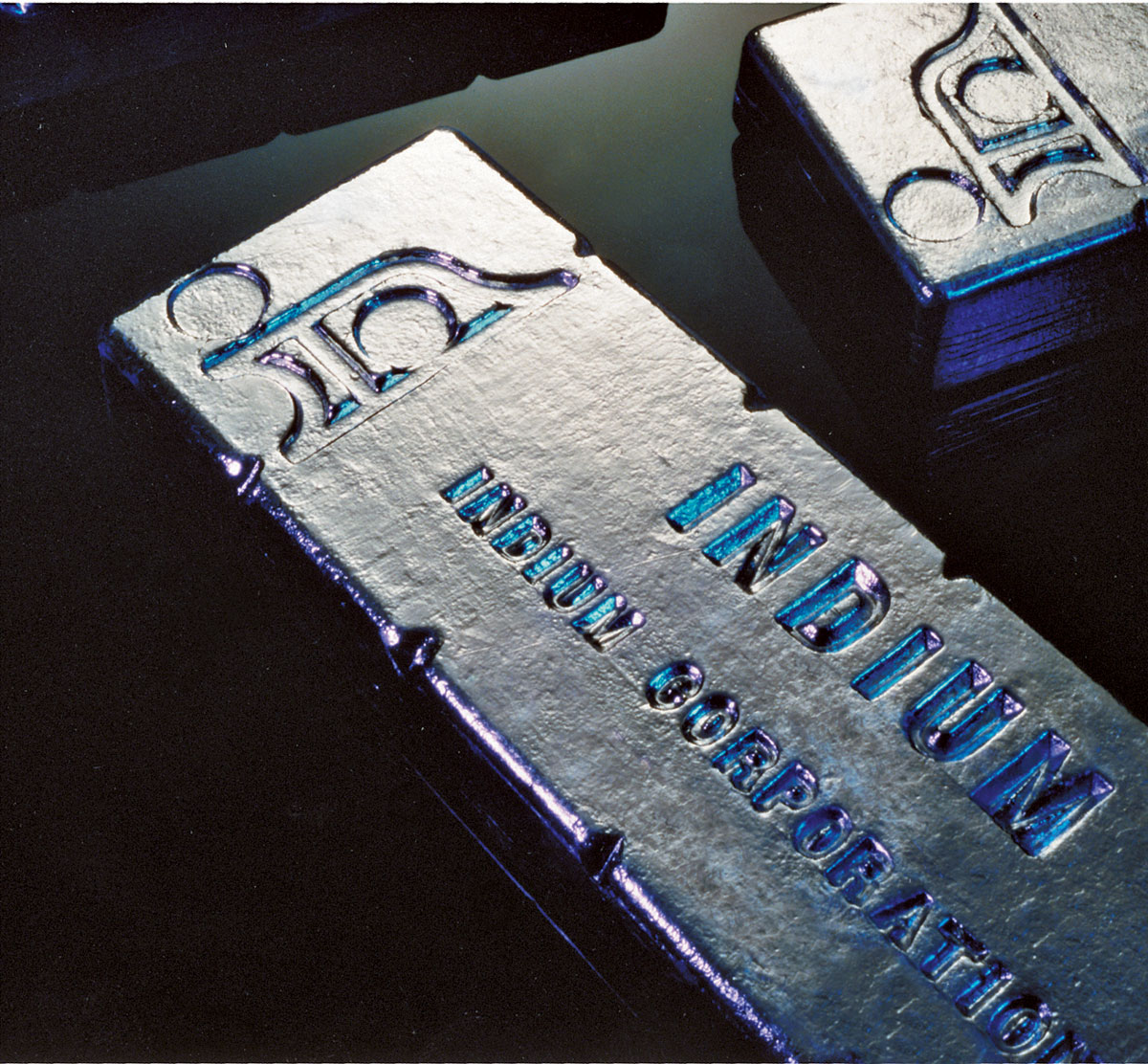

Read MoreIndium Corporation offers thermal evaporation materials for thin-film deposition. The purity of source material is as important as the equipment used for deposition. We offer the high quality materials and experienced technical support to help you get the most from your physical vapor deposition (PVD) process.

Below is a chart that outlines the types of materials and the forms in which you can get those materials.

| Material | Round Shot | Teardrop Shot | Chunks | Custom Forms | Crucible Filling | Custom Crucible Inserts |

|---|---|---|---|---|---|---|

| In | X | X | X | X | X | |

| ITO | X | |||||

| Ga | X | X | ||||

| InGa | X | X | X | X |

Physical Properties of Common Elements for Thermal Evaporation

| Indium | Gallium | Copper | Selenium | |

|---|---|---|---|---|

| Atomic Number | 49 | 31 | 29 | 34 |

| Boiling Point | 2072°C | 2204°C | 2562°C | 685°C |

| Melting Point | 157°C | 29.8°C | 1084°C | 221°C |

| Density | 7.31g/cm³ | 6.10g/cm³ | 8.94g/cm³ | 4.28-4.81g/cm³ |

| Atomic Weight | 114.8g/mol | 69.7g/mol | 63.5g/mol | 789.6g/mol |

Physical Properties for Common Alloys for Thermal Evaporation

| ITO | CuGa | CuIn | |

|---|---|---|---|

| Melting Point | 1500°C | 460°C | 575°C |

| Density | 7.16g/cm³ | 7.91g/cm³ | 8.45g/cm³ |