Applications

Burn-In Test

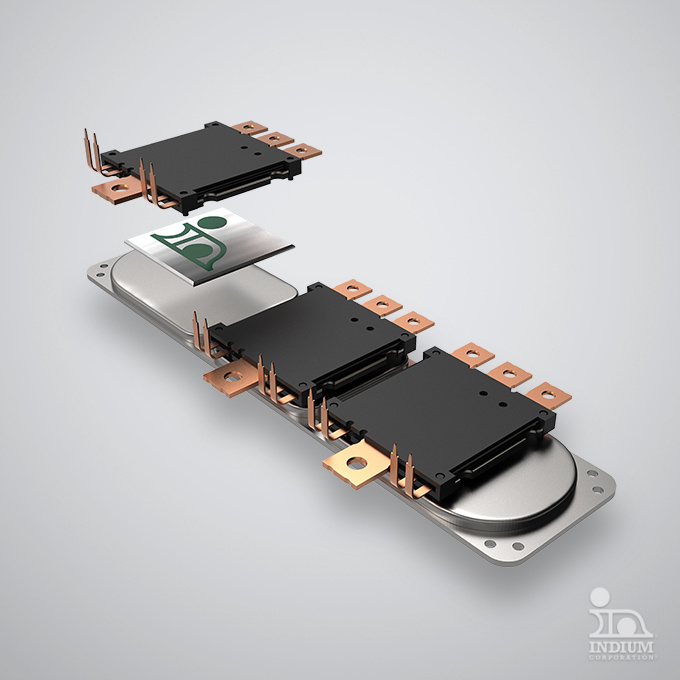

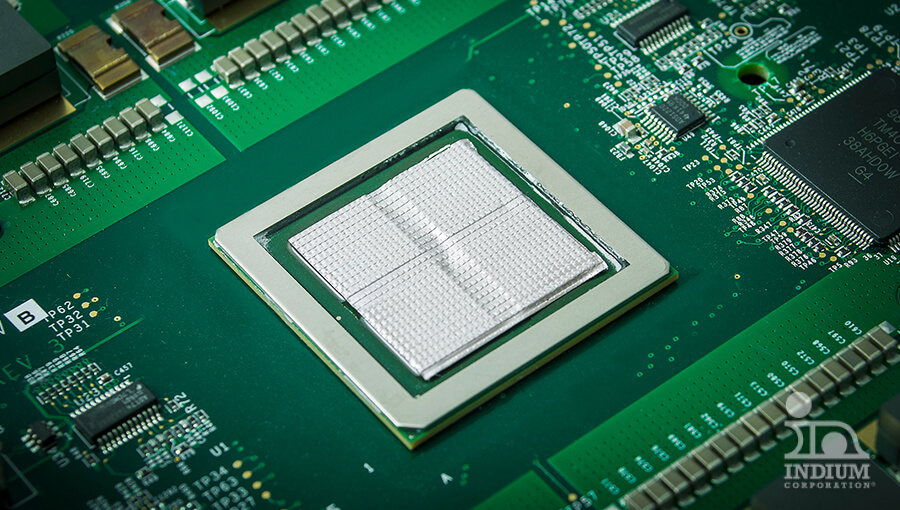

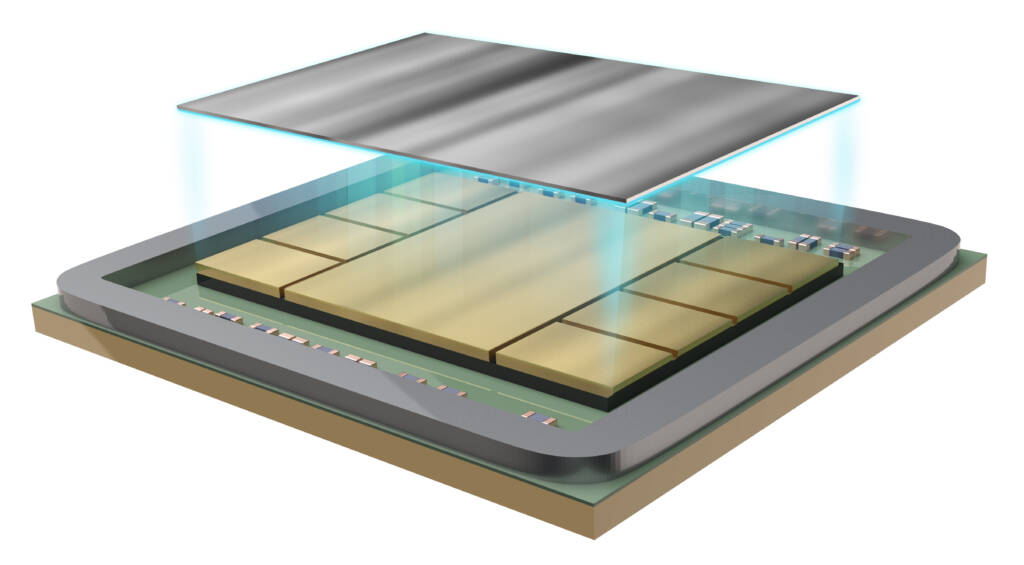

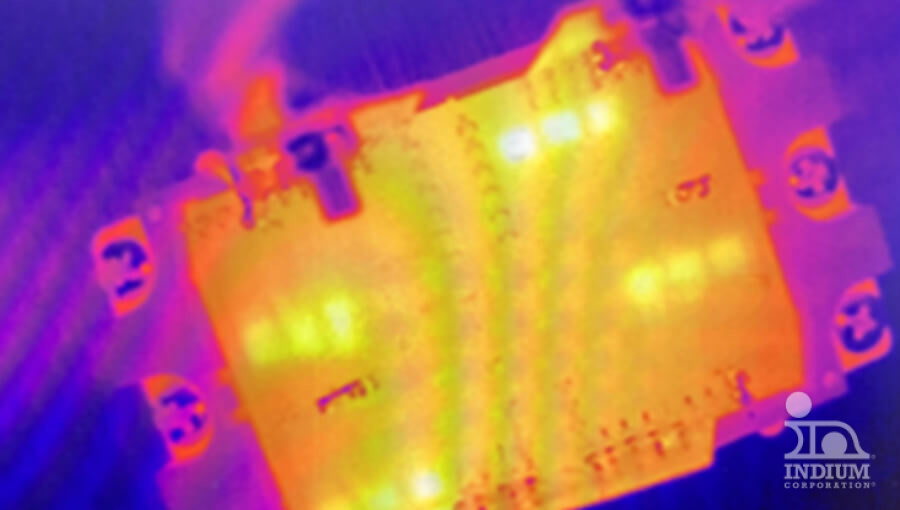

The most stringent application requirements for thermal interface materials (TIMs) are found in semiconductor testing. This environment presents challenges such as increased power, elevated heat flux, larger die sizes, and greater warpage that must be effectively managed. For semiconductor testing, compressible soft metal alloys like indium have become the industry standard. Specifically engineered for burn-in and testing processes, these recyclable materials support multiple insertions, improve process yields, and offer ease of use.

Overview

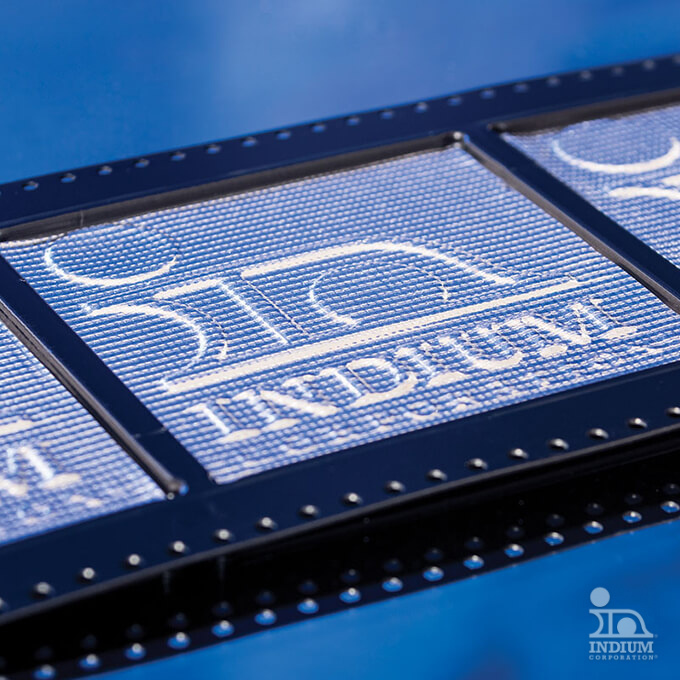

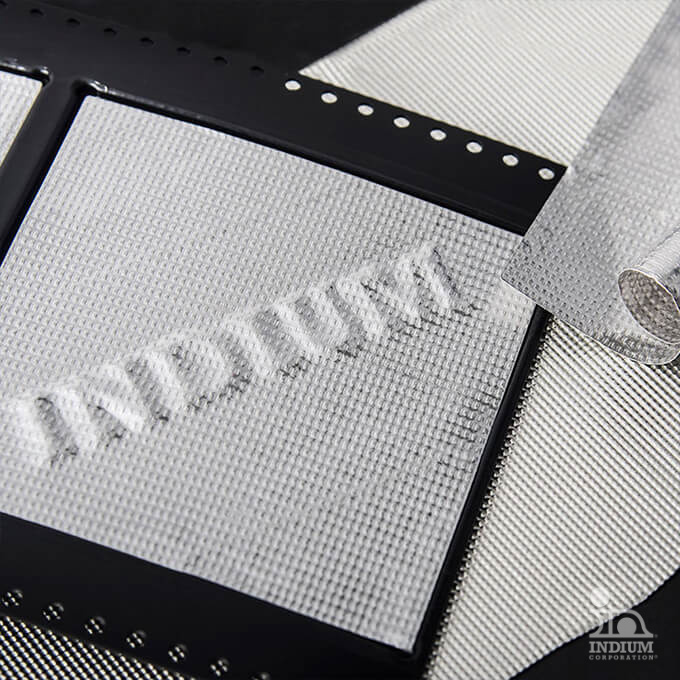

Improve Process Yields With Heat-Spring® HSK

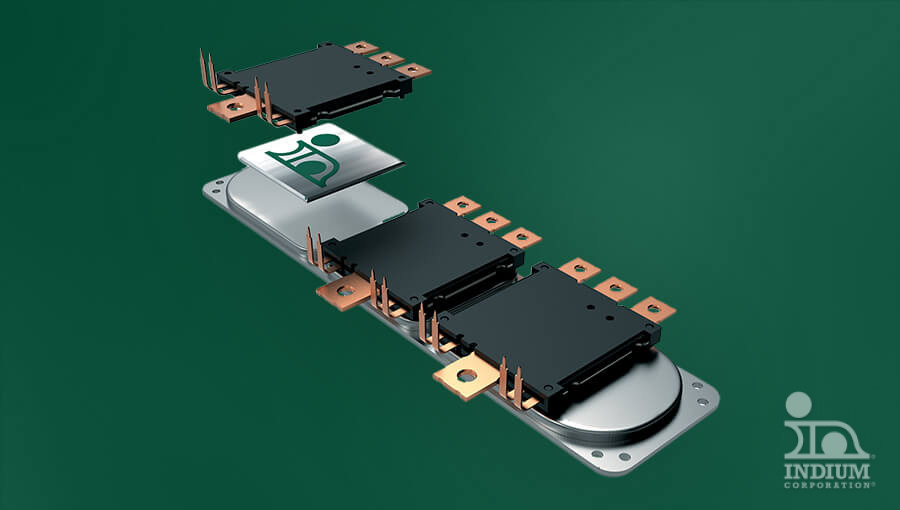

Heat-Spring® HSK features a textured pattern on one side and an aluminum-clad barrier layer on the other, ensuring durability through numerous insertions. The thin aluminum layer facing the device under test (DUT) prevents the soft metal from adhering to the surface, effectively reducing the risk of stains and cracks.

Benefits

Enhance Gap-Filling and Thermal Performance on Uneven Surfaces

Sustainable TIM

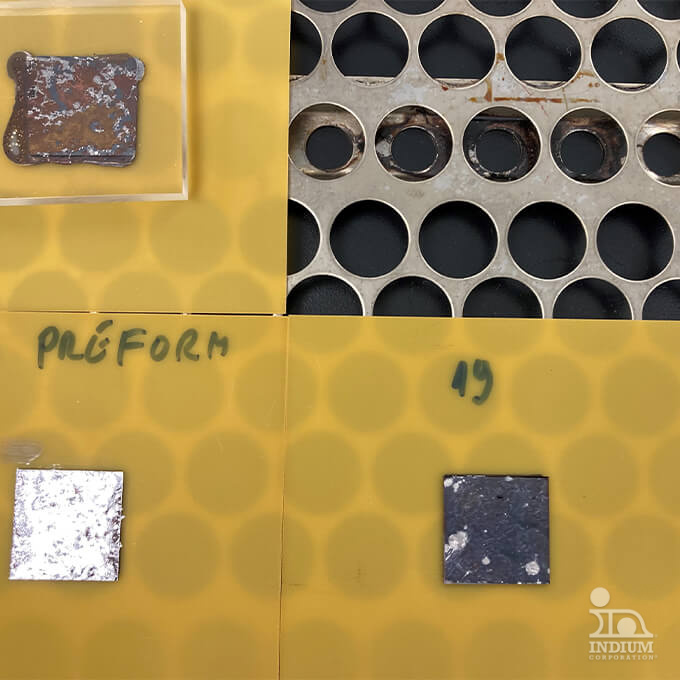

Metal TIMs are easy to handle, 100% recyclable, and eligible for credit upon return. Multiple alloys are available depending on operating temperature requirements.

Flexible

Adaptable formats can bend up to 90° and wrap around various test head/socket lid configurations, including gimbaled test heads.

Performance

Surface pattern designs reduce contact resistance, delivering thermal performance comparable to solder at 50 psi. New options for even lower pressure are also available.

Multiple Insertions

The aluminum-clad layer on the DUT prevents staining and sticking, allowing it to be used for hundreds of cycles.

Related Applications

Related Markets

Your Success

is Our Goal

Optimize your processes with the latest materials, technology, and expert application support. It all starts by connecting with our team.