Folks,

Last week Indium Corp held its annual Technology Summit. There were many excellent technical presentations. Chris Anglin's brought out some information I would like to share with you.

In stencil printing of fine features, the area ratio (AR) of a stencil aperture is an important metric. AR is defined by the area of the stencil opening divided by the area of the side walls. For a circular aperture this is:

AR = Pi * r2 / (2Pi * r * t) = r /2t or D / 4t, where r is the aperture radius andt the stencil thickness (D = 2r).

Experience has shown that for successful printing, AR should be >0.66. Chris pointed out that successful printing is more dependent on consistancy (small standard deviation) among the printed solder paste deposits than a transfer efficiency (TE)close to one. Transfer efficiency is the ratio of the volume of the printed deposit divided by the volume of the aperture. In other words, you can have successful printed with a TE of say 0.5 as long as the variation among the deposits is small.

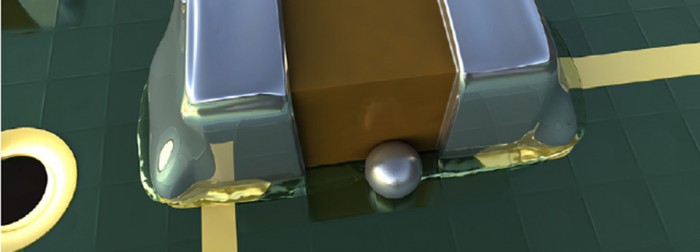

What was most surprising to me was the AR of common objects. Chris used this approach to convey the concept in terms of objects that we can relate to. The can ofBumble Bee tuna in the photo has an AR of only 0.49! Intuitively, I think most of us would have thought that an aperture with the dimension ratios of atuna canwould be good for printing. Chris points out that it is low by almost 20%.

AR shows the extreme challenge of 01005 printing. To print for these small passives, the aperture will need to be about 6 mils. To have an AR of = 0.66, the stencil thickness must be t D/ (4*0.66) = 6/(4*0.66)= 2.3 mils. Since most other devices would might need a 4 mil or thicker stencil to obtain enough solder to make a good joint, a step stencil or two printing steps may be needed for successful 01005 assembly.

AndI'll betpeople are working on a developing an 0050025 passive. Yikes!

Cheers,

Dr. Ron