For this week’s World of Solder Preforms series installment, Brandon Judd explains the importance of reflow profiling:

Solder preforms are a very common method of reducing voiding in a soldered device with larger X/Y dimensions. Compared to solder paste (which is approximately 50% flux by volume), flux-coated solder preforms generally contain only 0.5 to 2% flux by weight. In some cases, such as when using AuSn preforms on Au surface metallizations, you can even solder completely fluxlessly!

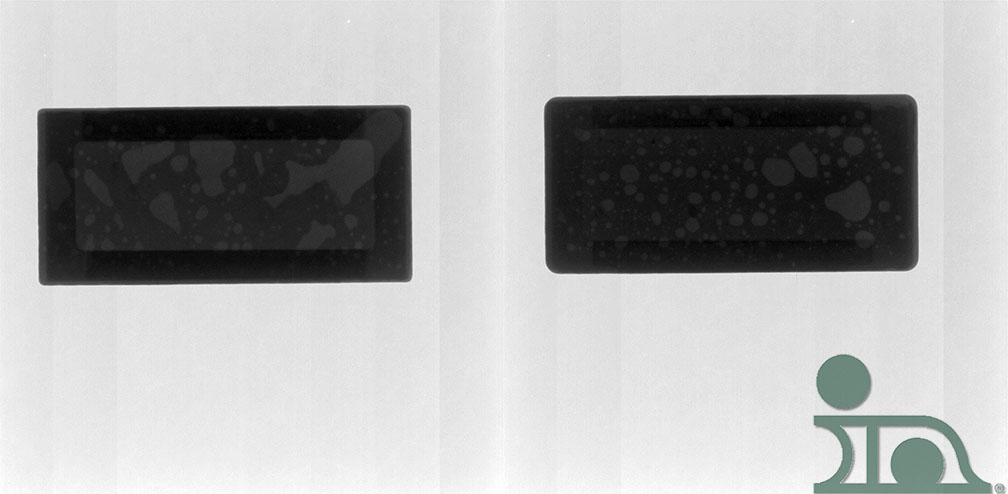

Reducing the quantity of flux means there is less outgassing during reflow, and therefore less voiding. Reflow process optimization can further improve the voiding performance of solder preforms. For comparison:

- below on the left is an x-ray image of a flux-coated 63Sn 37Pb preform sandwiched between Ag-plated coupons, reflowed with a longer soak style reflow profile

- while the image on the right depicts the same stack-up with a shorter ramp-to-peak style reflow profile.

The linear ramp-to-peak reflow profile shows a noteworthy improvement in the voiding percentage of the solder joint. Of course, each application may require a slightly different reflow profile, depending on several parameters such as solder alloy, surface finish, and thermal mass of your assembly. For help selecting the best preform and optimal reflow process for your application, contact one of our technical support engineers at [email protected]. –Brandon Judd

Brandon knows reflow profiling. Check out his blog here: Link to Brandon Judd’s Blog.

*This post is part of the World of Solder Preforms series