A well-respected colleague asked this week if the metal loading of type '4' solder powder in a paste was lower than that for type '3' because the particles were smaller. The implication being that smaller and smaller particles will fill up more and more volume. He is correct in that typically, in solder paste made from type 4 solder powder, the metal loading is usually slightly lower than that for the same alloy in type '3', but not for the reasons he is thinking of. Bear in mind that (per the ANSI/IPC powder J-STD-006A, the type '4' is typically between 25 and 38 microns, while the type '3' is from 25 to 45microns in diameter, so the type '4' is just a smaller range of particle diameters.

There are two aspects of this: the geometry of solder particle packing… and some things we can lump together under the heading of "harsh realities".

Particle-Packing:

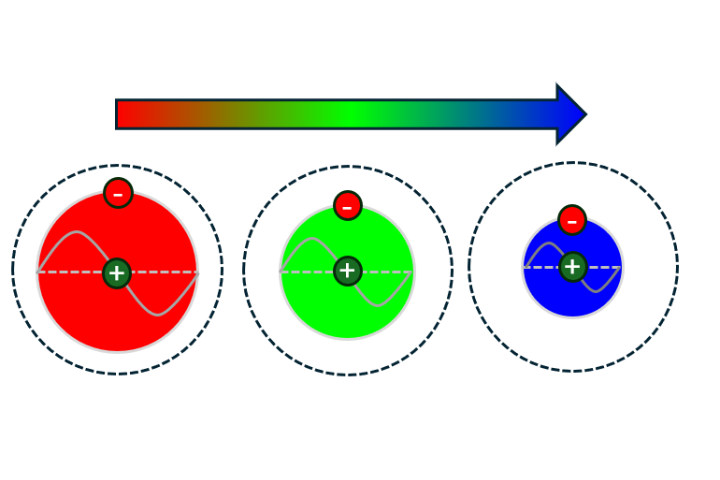

Just from a theoretical point of view (monodisperse powder diameter / perfectly spherical particles), the maximum volume that can be occupied by these particles is 0.740. This is the so-called "maximum packing fraction". You can prove this yourself by taking a triangular prism as a unit repeating cell and calculating the volume of fractional-spheres inside it – see the picture for the two ways that hexagonally-close-packed spheres can be arranged – the math is easier for the A-B-A packing. Note that this is [I}independent of the diameter of the particles[/I], which is counter-intuitive, but nonetheless correct. In other words, no matter how small the particles are, you should always be able to get them to achieve a maximum volume fraction of 0.74.

For randomly-arranged spheres, the maximum packing fraction is usually agreed to be somewhere between 0.67-0.69. Of course, at the maximum fraction, any solder paste would just be a solid mass, and the typical volume fraction of a solder paste is from 0.4 to 0.54 by volume of solder (from 75-93%w/w powder, depending on the alloy and the application).

So to achieve the same viscosity needed for the application, you need less volume of solder powder, and hence less % by weight, if the powder is more monodisperse.

Theory is nice, but we'll talk about the "harsh realities" of solder paste in the next post.

Cheers! Andy