Dear Dr. Ron,

We are experiencing some graping on BGA solder joints. One of my colleagues said he heard that using square versus our current round stencil apertures might solve the problem. This seems fishy to me, since the amount of solder paste difference isn't that great, I'm surprised that it could make that much difference. Can you shed some light on this issue?

Thanks in advance,

Eric

Dear Eric,

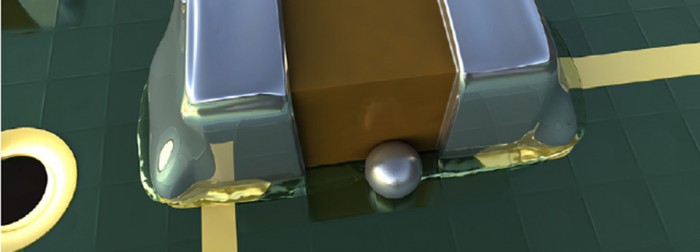

Your friend is likely right. Even though the volume difference between a round and square aperture is not great, calculation shows that the round aperture provides 0.7854 of the volume of the square aperture. So, square apertures have only a little more than 20% more volume. See Figure 1.

Figure 1. The circular aperture is only 78.54% of the volume provided by a square aperture.

The circular aperture is only 78.54% of the volume provided by a square aperture. However, experiments have shown that square apertures provide up to 40% more solder paste than round apertures. Discussions I have had with people that are knowledgeable in stencil printing suggest that the curvature of the circular aperture provides more contact to the solder particles than a square aperture. See Figure 2. This increased contact could result in more adhesion of solder particles to the aperture, resulting in less transfer efficiency.

Figure 2. The curved surface of the circular aperture provides more contact area for solder particles to adhere to, hence reducing solder transfer efficiency.

The curved surface of the circular aperture provides more contact area for solder particles to adhere, hence reducing solder transfer efficiency. Graping is caused by the oxidation of solder paste particles. So, if square apertures provide more solder paste, how can this reduce graping? Solder paste deposits today are very tiny compared to what they were just a few years ago. These small deposits have a large surface area to volume ratio. This situation requires the oxygen barrier components of the solder paste flux to work overtime to protect the solder particles from oxidation during reflow. A larger solder paste deposit, such as provided by the square aperture, minimizes this oxidation risk. This effect can be seen experimentally in Figure 3.

Figure 3. The square aperture eliminates graping as compared to the circular aperture.

The square aperture eliminates graping as compared to the circular aperture. It should be pointed out that modern solder pastes have also be designed to minimize graping. So, working with your solder paste vendor to solve a graping problem is also a good idea.

Cheers, Dr. Ron