Joey writes:

Dear Dr. Ron,

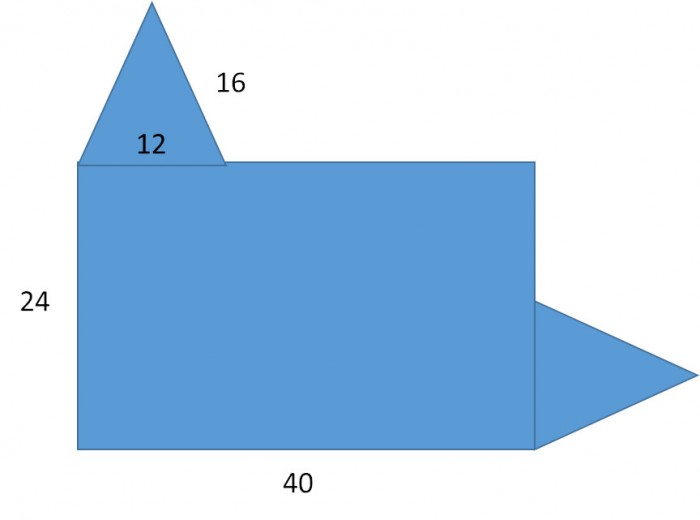

I have a stencil aperture with an unusual shape. See Figure 1. How do I calculate the area ratio? The stencil thickness is 5 mils. The dimensions of the aperture are also in mils.

Figure 1. Joey's Stencil Aperture

Thanks,

Joey

Joey,

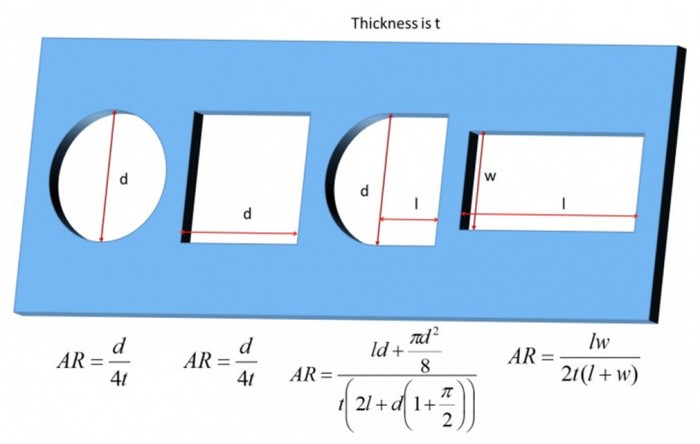

The area ratio is simply the area of the stencil aperture opening divided by the area of the sidewalls. For common aperture geometries such as circles, squares, etc. it is easy to derive formulas. See Figure 2.

Figure 2. Formulas can be developed for common aperture shapes.

For an unusual shape like yours, it is easiest to simply calculateand divide the areas. From Figure 1, we get that area of the aperture opening as: 40*24+ the area of the two triangles. A little geometry (can you do it?) shows each triangle to have an area of 89 sq mils. So, the total area is 960 + 2*89 = 1138 sqmils. The perimeter is 40+24+16+16+28+12+16+16 = 168 mils, hencethe area of the sidewalls is 168*5 = 840 sq mils. Therefore,the area ratio is 1138/840 = 1.355. Experience has shown that an area ratio of > 0.66 is needed for good solder paste transfer efficiency, so this stencil aperture will do well for transfer efficiency.

Careful thought would suggest that the triangular protrusions alone do not have a good area ratio. Calculations show their area ratiosto be 0.37. So, the transfer efficiency in this part of the aperture might not be good. However, the area of the rectangle is so great, more than five times that of the triangles, as to alleviate this concern.

Dr. Ron