Introduction

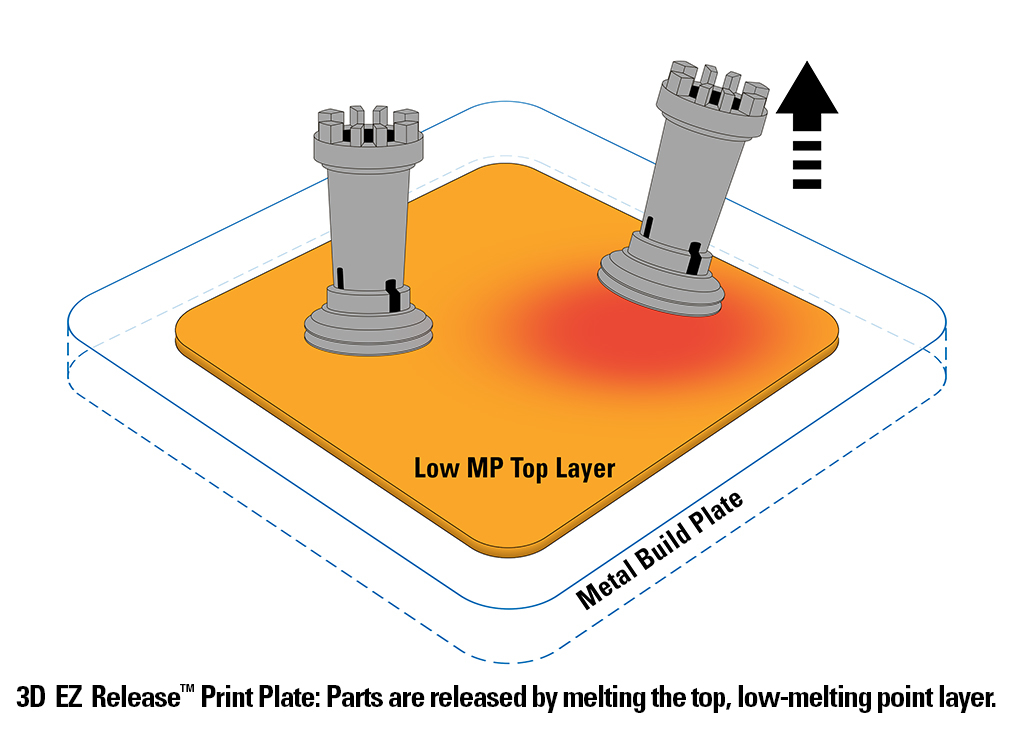

Indium Corporation is introducing the patent pending 3D EZ Release™ system for print plates used in powder bed fusion (PBF) printers. This system makes the removal of parts after 3D metal printing fast and simple.

PBF printers are capable of creating the most advanced metal parts, in a wide variety of build materials. However, in the standard PBF process, the printed parts are fused to the build plate and need to be mechanically separated using an electrical discharge machine (EDM), wire saw, or some other form of cutting tool. This can be time consuming and costly.

Features & Benefits

Indium Corporation’s 3D EZ Release™ print plate addresses one of the key pinch points in metal PBF printers—the high cost and long processing time needed for separating the printed part that is fused to the print plate.

Most PBF printed parts are separated using an EDM cutting process; this is costly and time consuming. The print plate needs to be refinished after cutting, and then after every print run. These steps are eliminated with our 3D EZ Release™ print plate.

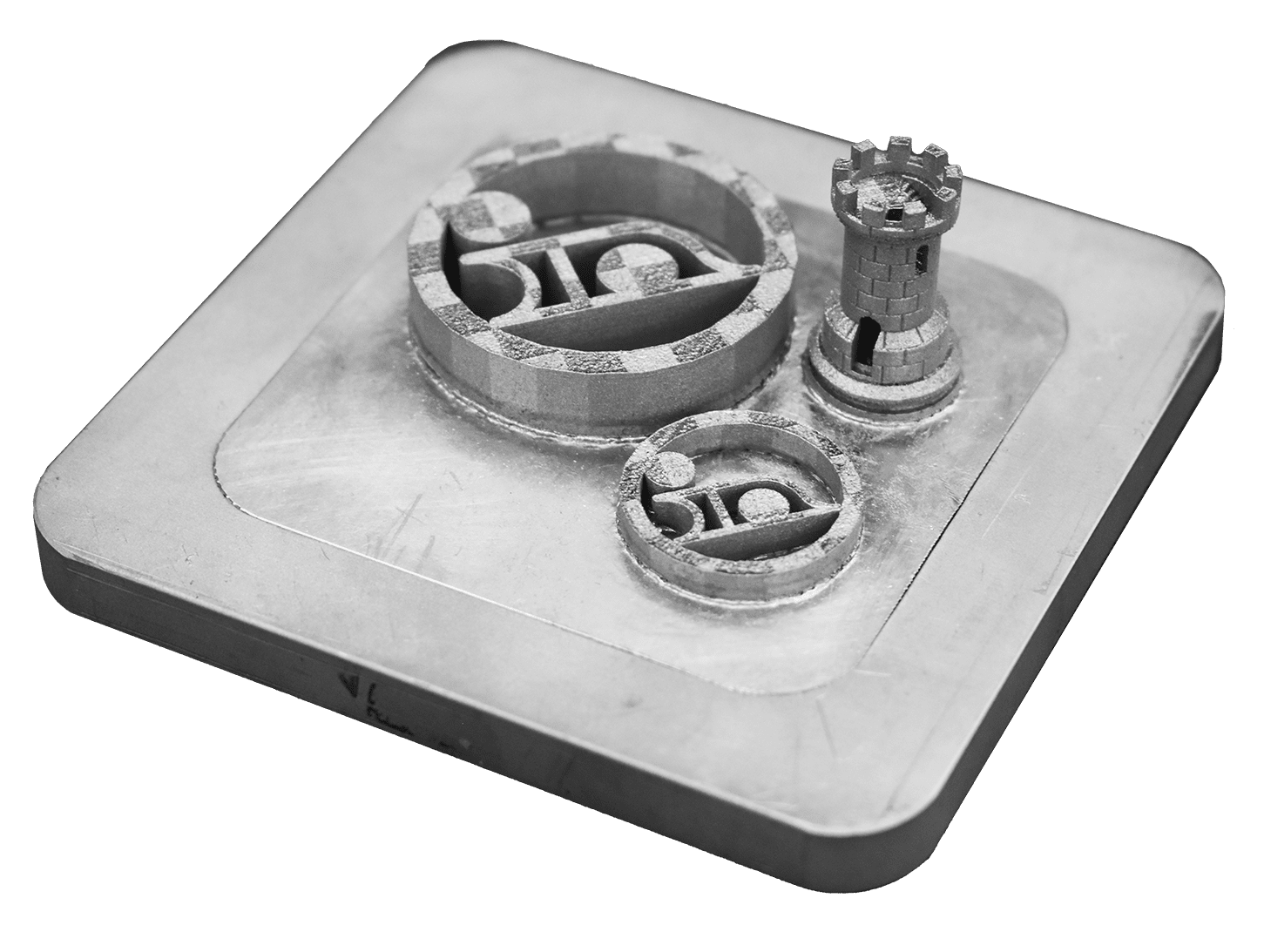

Our build plate contains an inlayed top layer that consists of a low-melting point alloy with a high thermal conductivity. We have printed numerous stainless steel parts on 3.5″ 3D EZ Release™ plates. After removing the plate from the PBF printer, the separation process consists of putting the plate in an oven heated to 200°C, and within a few minutes, the inlay layer will start melting.

The 3D EZ Release™ Print Plate video demonstrates this process.

3D metal printed parts removal is fast and simple through the 3D EZ Release™ system. Parts are released in seconds!

After the separation process, the fusible alloy will cool down and reach its solidus point; the plate should be placed on a level surface as it cools. If a soft recoater blade is used in the 3D printer, the plate will be ready for the next print run.

We have demonstrated this process on 3.5″ plates on a GE Additive Manufacturing / Concept Laser Mlab Cusing printer with a laser power at 100W.

We are in the process of adapting the technology for higher laser powers as well as larger print plates.

FAQs:

How long does the separation step take?

The plate from the finished print run needs to reach a temperature of 200°C. While the ultimate time to reach this temperature will depend on the oven and the thermal mass of the printed parts, a soak period of five minutes should be adequate to ensure melting of the alloy.

How often can the 3D EZ Release™ plate be re-used?

Each plate is designed to be used once to ensure the highest quality printed parts. You can quickly swap out the 3D EZ Release™ print plate with another and you are back to printing.

Does the alloy diffuse into the printed parts?

No diffusion of alloy material into printed parts has been observed.

Are there special design considerations for the print designs to work with the 3D EZ Release™ plate?

We have printed many parts that printed exactly as designed, with the number of layers in the low thousands, i.e., print parts approximately one-inch high. As in other metal 3D designs, corners should be avoided, if possible, in favor of rounded part geometries. The contact area to the plate surface should be minimized and the same considerations (support structures, down skin) apply as in general metal 3D printing. Of course, every design is different. We encourage you to work with us and send us your feedback from print runs.

For quotes and evaluation samples:

Contact Us