Dr. Andy Mackie recently put together a model to determine the probability that a component can be successfully dipped in solder paste or flux. Here is a little more from him on this subject:

"A customer in Asia was asking why one of our no-clean package-on-package fluxes, the ultralow residue NC510, was not allowing the PoP device to be picked up from the dipping tray. It turned out that the customer was allowing the flux to coat the whole of the bottom of the component, not just the solder bumps, so the vacuum nozzle had insufficient force to extract the PoP package from the flux . I got thinking about how I would model this from a physical viewpoint.

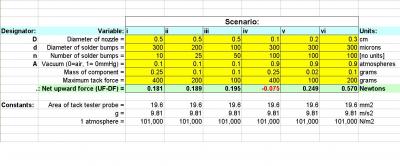

If the downward force (weight of component plus tack of flux) is greater than the upward force (air pressure on the bottom of the component), then the component could not be extracted from the flux. The figure shows the different variables. Expressing this mathematically, this comes out, in SI units, as:

Downward force = m.g + n.Ft.pi.(d/2)^2

where Ft is the tack force in units of mass per unit area, taken from the maximum tack force determined by the Tack Test Method from J-STD-005, ANSI/IPC TM 650:2.4.44

Upward force = 101000.A.pi.(D/2)^2

where A is the measure (fraction) of atmospheric pressure and denotes how good the vacuum is (zero vacuum is 0.0 : hard vacuum is 1.0).

There are some uncertainties with this approach: How does the vacuum vary across the nozzle diameter? Does the 5mm diameter flat IPC probe equate to a much smaller sphere? and so on, but it at least puts us in the right ballpark.

Just to give you a feel for how this works, the second figure shows some data. Note that scenario iv is the only one showing problems (negative force balance). The data implies that you are only likely to see an issue with inability to pick up PoP components from a dipping PoP flux tray if either:

- Components: Heavy and have many large PoP solder bumps

- Vacuum Nozzle: Too small and the vacuum is weak/poor

- Flux: Very tacky (high tack force)

and certainly, if the customer dips the whole bottom of the component into the flux, this opens up a lot of issues, including reliability (SIR); component displacement during reflow; as well as inability to pick up the component from the tray. This is why we always recommend a flux dipping height of 40-50% of the PoP bump height, to eliminate these issues."

I have found this model not only interesting, but useful for technicians to use when asked why components are 'only dipped 50%'. As a technician, it is good to have a scientific reason to refer to - even though experience may have already proven the theory to us personally.