All metals can be cold welded, but need significant shear between the two pieces. Indium ("the easiest material in the world to cold weld*") is unique in that it can cold weld to itself at extremely low pressure. Other metals need extra force to break through the surface contaminants (oxygen, carbon, etc.) to effect the weld. This has to be done with significant pressure/friction that would result in heat (friction welding). The two materials can be combined with solid state diffusion by increasing the temperature to about 50-70% of the absolute melting temperature of the metals (Diffusion Welding).

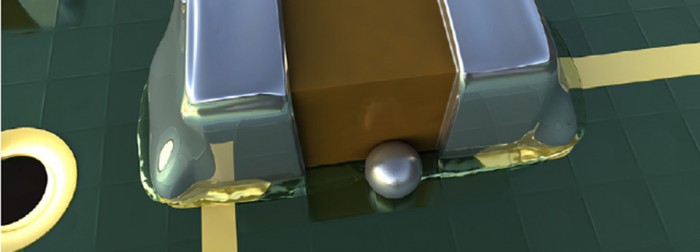

Indium, however, can do this (cold weld) through contact alone. This is assisted by the low melting temperature of indium. As for indium alloys, they can also be cold welded, but, as you add more elements to indium, you “poison” its properties. Therefore, even though these indium alloys can be cold welded, they will need some combination of heat and pressure to form joints with good integrity through cold welding. If you would like to see a picture of indium cold welding, check out my post titled, "The Result of Cold Welding Indium."

If you have more questions please feel free to reach out to me or email [email protected].

*https://boingboing.net/2017/02/10/cold-welding-metal-together-on.html