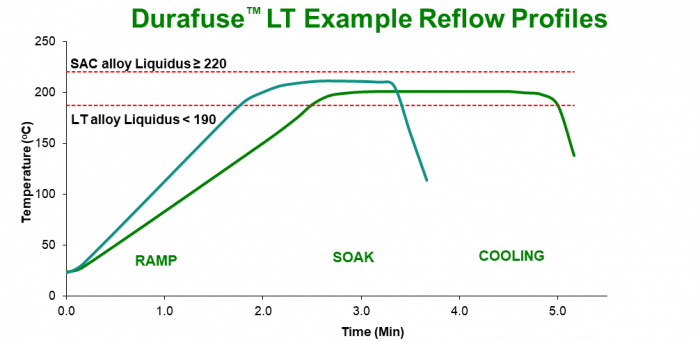

Low-temperature solders can have a wide variety of reflow profiles. One of the great things about Durafuse® LT is that it opens up an entirely new set of options for combining low oven temperature with high drop shock performance. Still, reflow for a mixed alloy solder paste may seem more complicated than it is - and understanding the terminology may be helpful.

Not too long ago a coworker pointed out that I was occasionally using different words to refer to part of the profile for Durafuse® LT: to which I will say "sorry!" and "thank you!" because now I have the opportunity to share how the reflow profile for Durafuse™ LT is as straight forward as any other solder.

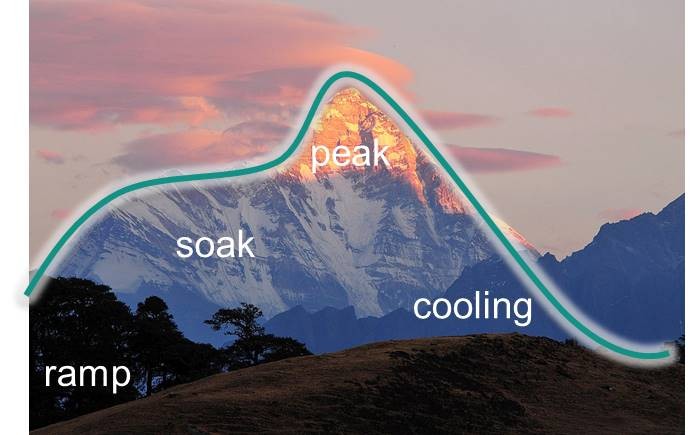

For instance, in blog on how to change a profile for specific board characteristics, she talks about "ramp", "soak", and "peak". Then at the end there is the "cooling" stage. The trick is remembering that for Durafuse® LT: we use all the same words.

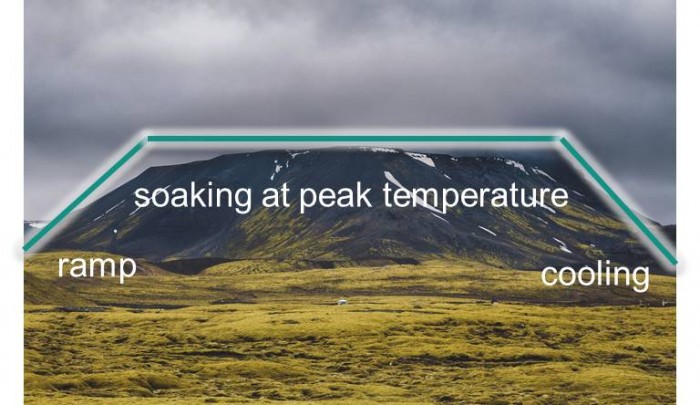

Now we get to the only major difference: looking at the profile shape. The peak temperature is held constant for between 40-160 seconds to improve the joint capability (which can even be used in other solder systems!).The solder is at the peak temperature, but the profile isn't shaped like a mountain "peak". No worries - it's still "peak temperature".

The only challenge is referring to "time at peak temperature" because most of us are used to "time above liquidus". Well, I struggled for a while before realizing even this didn't need a special phrase. Meagan already used the right word: a "soak" happens when the board is staying at a constant temperature instead of ramping up or down. This is true even if it is happening at the peak temperature. Maybe I'm just stating the obvious, but I went an awfully long time being inconsistent (Whoops!)

Fun tangent: The shape of a many profiles really do look like mountains, right? If we keep the geography theme going, the profile shape for Durafuse® LT is a plateau!