Folks,

Ken writes:

Dr. Ron, Thanks for your helpful post. I get close (-1.1%) with your formulas for an alloy I am working with. I think the crystal lattice packing factor for some of the individual elements is throwing off the result since it is different than the alloy. I tried to take this into account, but I get an error on the opposite side (+1.6%) of the actual. Any thoughts on if your formula can be made more accurate by taking element and alloy crystal lattice packing factors into account?

The solder alloy calculation assumes that the metals mix with no interaction, much as miscible liquids, of different densities would. There are numerous phenomena that could cause errors, they include:

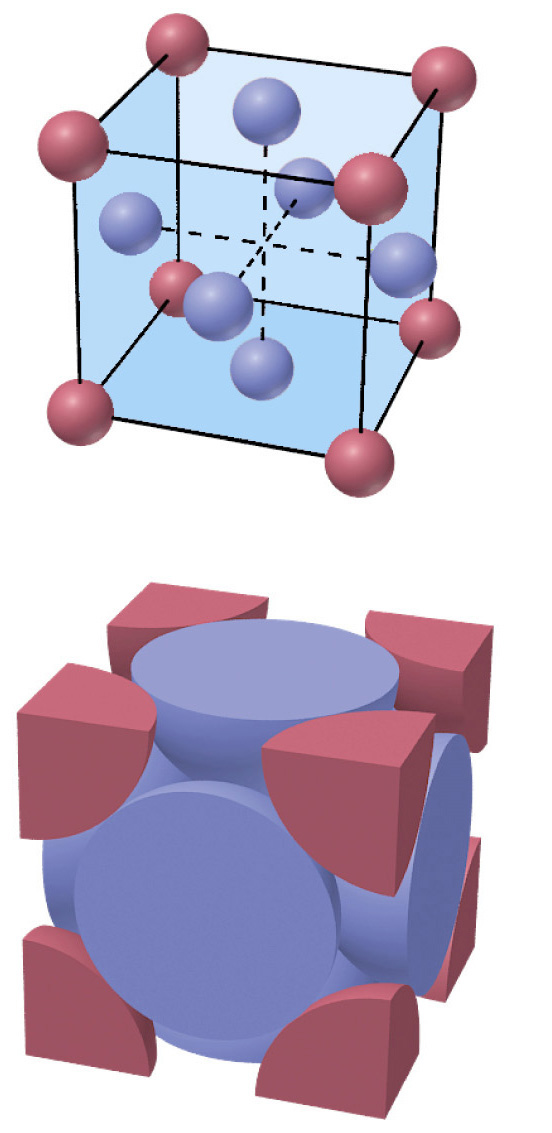

1. Metals can come form different crystal systems. Lead, silver and copper are face-centered-cubic, whereas tin, the base metal for most solders, is of the tetragonal system.

2. Some metals form intermetallics with tin, such as copper and silver. These intermetallics have different densities than the metals or the resulting alloy.

3. Grain boundaries can leave some (probably small) empty space.

So I think Ken's 1% accuracy is very good. The biggest mistake one can make however, is the most common......assuming that the density is simply given as the sum of the metal mass fractions times the metal densities. To many, it seems logical, but it is wrong.

My original posting on how to derive the formula for solder alloy density is below.

Cheers,

Dr. Ron