Flux is an essential component in the creation of a solder joint. For the sake of this post, I will be referencing flux as it is used in wave soldering machines. But, if you want to know of other uses, check out my colleague, Jim Hisert's, blog: Specifying Solder Preforms - Flux.

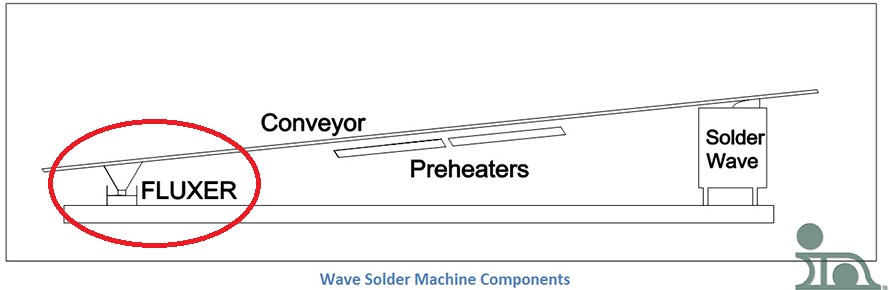

When wave soldering was first developed, the flux was commonly applied using a brush method in which a technician would apply the flux using, you guessed it, a paint brush. As you can imagine, this was not the most controlled operation. Automation was needed to increase productivity, accuracy, and consistency when applying flux. The different methods created and discussed in this series are:

When automation is initiated, certain regulations need to be implemented, such as the operating rules for fluxers, along with flux addition and flux density control. There are also certain strategies that are implemented, like the total loss system that will be discussed in parallel with the spray fluxer.

'Til next time,

- Adam

Stay tuned for the next installment: Fluxers Part I - Foam

*This is the second post of Wave Soldering (A Segmented Synopsis) Series