So, high-reliability alloys: what does that mean and why?

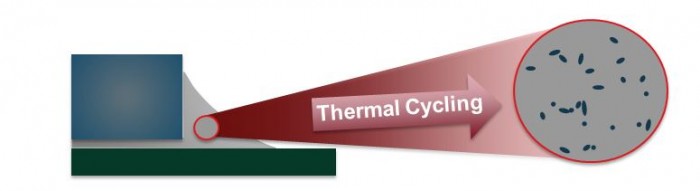

The "what" is actually pretty easy in this case. Alloys such as Indalloy®292 are used to improve thermal cycling performance. That means we get less cracking in the solder joint over time, which means fewer failures! Okay, but why are they more reliable? What's going on? I'm no metallurgist, but I've talked to a few here at Indium Corporation, and they've helped me out a bit.

Unlike eutectic Sn-Pb solders with 2 elements, and the commonly used 3 part Sn-Ag-Cu solders, Indalloy®292 contains 7 elements. The metallurgists do a lot of work balancing properties like liquidus temperature, wetting, ductility, etc. However, for reliability, one of the most important interactions is between the tin and the antimony in the solder joint.

Extremely small (under 2um!) in-situ SnSb particles form within the overall crystal structure of the solder joint. These particles are solid state precipitates and actually strengthen or reinforce the overall solder joint matrix (reducing crack growth). With the relatively high concentration of antimony in Indalloy®292, during high temperature thermal cycling up to 150°C, the number of SnSb particles will actually increase. This is great for joint strength.

Another good thing about these SnSb particles is how they grow very slowly. With time, the crystal grains in solder joints grow and coarsen. My not-metallurgically trained self is interpreting this to be like old ice cream, which gets really grainy in the freezer over time. Unfortunately, as with ice cream, this is not exactly a good thing. For the solder, coarser grains make it easier for cracks to grow along the edges of the crystal grains.

So, in summary, we are now in agreement that it is important to eat ice cream in a timely fashion. I recommend chocolate chip cookie dough. In addition, I hope you enjoyed learning a little bit about what is happening inside the metal of a high-reliability alloy. Isn't material science crazy and amazing?