Indium gaskets? You have probably heard of automotive head gaskets and plumbing gaskets and even gaskets used in sailing (that was a new one to me!). But have you heard of indium metal gaskets?

The general function of a gasket is to provide a seal between two surfaces to either keep something in or keep something out. A gasket made of indium has some key qualities that make it ideal for creating seals, especially in harsh environments:

- Indium metal is soft and pliable and when it is put between two surfaces, it will fill any imperfections in those two surfaces, providing a hermetic seal. Other materials might just cover imperfections and the resulting seal may have gaps.

- Indium retains its malleability down to cryogenic temperatures so it can be used in harsh environments, like outer space, and the seal will not crack.

- This seal can be made mechanically, meaning you can just apply pressure without applying heat. This is especially useful in applications where applying heat or using a solder flux (that might outgas) are not options.

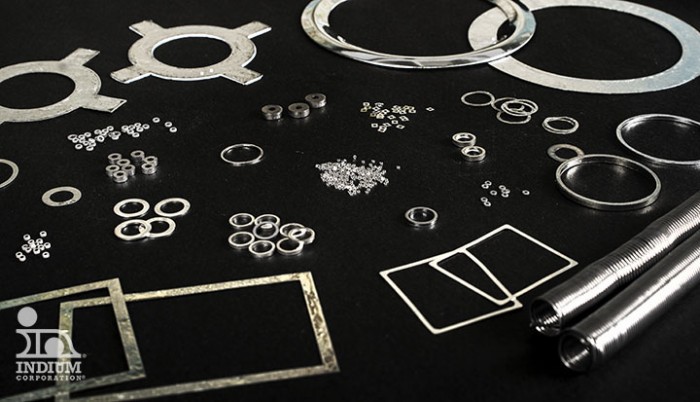

- Indium can be made into a wide variety of shapes and thicknesses to make the perfect seal for any application.

Indium Corporation has been making seals since 1934. We manufacture flat gaskets or pure indium wire so you can form the gasket yourself. Wire is most often used when one of the surfaces is a channel and the wire can be seated inside the channel.

It is always important to keep the indium as clean as possible (handle with gloves or tweezers) so nothing interferes with the sealing operation. Since indium is a metal, it will have surface oxides, but indium is self passivating, meaning it will grow oxides to only about 80-100 angstroms and the surface can easily be cleaned using our cleaning process.

You can learn more at our web page on sealing.