Folks,

The challenge of removing heat from electronics is almost as old as the 100 year old electronics industry. In modern electronics, most of the heat generated is by the integrated circuits (ICs) and it must be removed or the ICs will have a very short life. This heat transfer challenge is often a limiting issue in the design of electronics.

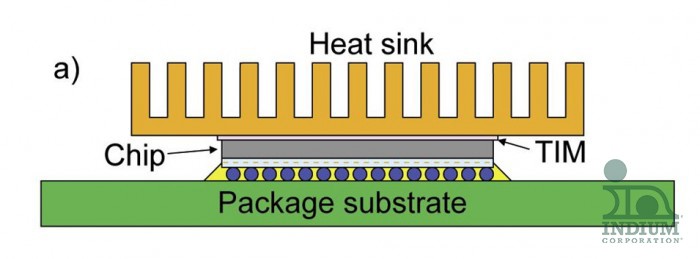

In many cases the thermal path or the path that the heat must travel from the integrated circuit to the heat removing fins is a critical design challenge. In its simplest form, the thermal path is from the IC chip through a thermal interface material (TIM) to the heat removing heat sink as shown in Figure 1. Other thermal paths exist, but are similar in the movement of heat. Examples are burn-in and thermo-electric cooler applications.

Figure 1. The simplest thermal path for an IC is shown above. The TIM is a crucual part of this thermal path.

Although at first the concept of a TIM might seem trivial, however developing a TIM that is low cost, effective and has a simple assembly process has been a decades long challenge. To effectively remove the heat from the IC, the TIM must conform to the surface of both the IC and the heat sink and bond the heat sink to the IC. If the TIM material leaves air gaps, the thermal path will be poor and the IC will over heat.

Thermal grease has been used as a TIM for years, but has the disadvantage of being a poor conductor of heat and often the process of applying the thermal grease is messy.

A new product has been developed to meet the TIM challenges. It is a thin foil of aluminum, one of the best conductors of heat, coated with a non-silicone thermal compound. This TIM not only has excellent thermal conductivity, but is easy to apply. The new TIM has already been successfully deployed in some burn-in and thermoelectric cooling applications.

Cheers,

Dr. Ron