Folks,

Looks like Patty has been busy.....

Patty couldn’t remember having a busier week. She just got back on Friday from serving on a review board for statistics projects that West Point cadets had worked on. Then, she and Rob had to put their Christmas tree up. On Saturday her family traveled to nearby Woodstock, Vermont for Wassail Weekend. Her young boys were very excited to see the parade. In the day of tablets and smartphones, this non-mechanized parade (everything horse drawn) was a welcome change. On Sunday, she and Rob participated at a Messiah sing along.

Every time she sang Messiah, she marveled that Handel could create his master piece in only 24 days!

But today was Monday, and, as she turned into the Engineering School parking lot at Ivy U, she had just finished an audio tape of Henry Kissinger’s new book World Order. She was stunned by Kissinger’s deep insights into world order. She hoped our politicians read the book.

Upon arriving at her office, she dove into the first of 108 emails. Right about in the middle of the stack was a request from a local company for help with improving their wave soldering operation. After reading it, she sent a text to Pete to come and see her. Pete arrived right as she finished the last of the emails.

“Hey, Professor what’s up?” Pete cheerfully asked.

“For the first time ever, I knew of something before you,” Patty teased.

“A local company, in Thetford, VT, needs some help with wave soldering. Can you help?” Patty went on.

“Sure! Glad to. What are the details?" Pete asked.

“None given, just poor yields,” Patty responded.

“What do you want to bet that it is insufficient pre-heat?” Pete opined.

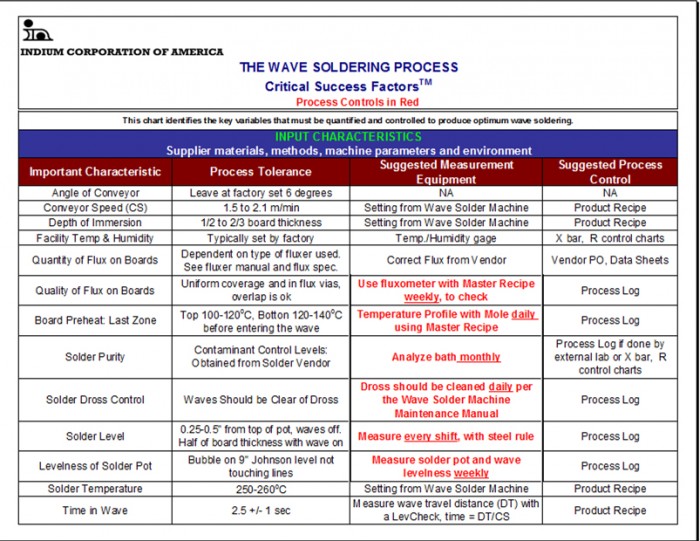

“You are probably correct. But, why not take the Wave Soldering Critical Success Factors Chart (see Figure 1.) we developed a few years ago and leave it with them after a little tutorial,” Patty suggested.

Figure 1. Page 1 of the "Wave Soldering Critical Success Factors." Page 2 is not shown. If you would like a copy send me a note at rlasky@indium.com

In the past, Patty and Pete had frequently discussed how insufficient preheat was often an issue with modern PWBs assembled via wave soldering. Many modern PWBs have a large thermal mass and, often, the wave soldering machine does not have top side heaters to help pre-heat the boards. This situation would often be an issue if the company had a lot of experience with light boards and then switched to heavy boards.

“How did your trip to West Point go?” Pete asked.

“The students all did a great job on their statistics projects. I have never been called ‘ma’am' so many times,” Patty chuckled.

“The most interesting talk was by a student who performed SPC analysis on some electronics assembly data. There was something familiar about him ... and then I saw his name tag, ‘Madigan.’ He is Mike Madigan’s son, Mark,” Patty elaborated.

“Small world. Sounds like he learned from his dad, who learned from you, ” Pete chuckled.

Pete left after a few more minutes. In one of the emails Patty had just finished, a chap from a Boston company was on campus. He asked if he could see her at 10:30AM about a DFM project. She had responded in the affirmative. It was a timely request, as she was just putting the finishing touches on a series of lectures on the topic.

Patty glanced at her watch; it was 10:25AM. She heard a knock on her door and a tall fellow of about 30 years of age stuck his head in.

“Hello, Professor Coleman, Don Jenson here. Is this still a good time?” Jensen inquired.

“Sure. Come on in,” Patty responded.

“I work for Vistion Medical Devices,” Jenson began.

“Our business is booming and we are making increasingly complex devices. Two years ago we were at 500 people, now we are 1,200, heading for two thousand,” Jenson explained.

“How is your DFM program right now?” Patty asked.

“Nonexistent,” Jenson replied.

Patty groaned inside. She marveled that a successful company could be competitive without a DFM program.

“The nonexistence of our program is why I am here. Two of my colleagues and I have been tasked to implement DFM, but the CEO has laid some restrictions on us. We are hoping you can coach us through it,” Jenson pitched, hopefully.

“I’m glad to help, but what are the restrictions?” Patty asked.

“I have a list. Let me show you,” Don replied.

Jensen unfolded a piece of paper, entitled DFM Restrictions, in front of Patty. On it were listed eight restrictions:

- Only 3 people will be involved in the DFM process. No others are to be disturbed by its implementation.

- Product design will still drive manufacturing.

- No vendors will be involved in the DFM process, as they will likely want to be paid extra.

- No established manufacturing processes will be changed.

- Parts and inventory control are not to be part of DFM.

- Design Guidelines are to be set by design engineering.

- The DFM program must support the outsourcing of 50% of production to China in two years.

- Cost reductions and quality improvements must continue.

Patty was dumbfounded. She stared at Jensen for a moment, not knowing what to say.

Finally, she asked, “Dave, what are your thoughts on these restrictions?”

“Well, given the little I have learned about DFM, it seems that all of these points but one go against the spirit of DFM,” Jensen responded.

“Agree. Only point 8 is consistent with a DFM strategy,” Patty said. Then Patty chuckled, “You could almost say that this list contains all of the things not to do in a DFM plan.”

“If there is one thing that exemplifies DFM, it is the involvement of the entire company; product development, manufacturing, procurement, quality, suppliers, and even shipping. You can’t have an effective DFM program without the total involvement of everyone in the product cycle. Most important is the passionate commitment to DFM by the CEO,” Patty summarized.

Patty then lent Jensen a few books and developed a study plan for him. After learning about DFM, he would develop the right type of plan and, if needed, Patty would help him sell it to the CEO.

As they were wrapping up, Patty felt the need to elaborate on outsourcing.

“I’m just developing a lecture on the negative effect of outsourcing. It is covered well in “Design for Manufacturability and Concurrent Engineering” by Dr. David M. Anderson, “ Patty began.

“Anderson points out that outsourcing violates almost all principles of DFM as the development, manufacturing, quality, and procurement teams are separated by 1,000s of miles, many time zones, and different languages and cultures. Since much of the final cost of a product is in engineering changes, the savings in labor is usually more than eaten up by engineering changes and shipping. In addition, most people don’t consider the tremendous cost of managing outsourced manufacturing, “ Patty summarized.

“Perhaps this is why I keep hearing about ‘reshoring’,” Jensen responded.

“There is even something called the “Reshoring Initiative” to encourage bringing jobs back to the US,” Patty said.

As Jensen left her office, Patty was glad to have helped, but sensed that he had a tough task before him. Understanding that DFM was a way of life for everyone in a company and especially that outsourcing was not part of DFM was still not appreciated.

Cheers,

Dr. Ron