The folks at Advanced Packaging magazine asked Indium Corporation for its predictions for the Standard Semiconductor and Power Semiconductor packaging market in 2009. I was happy to oblige.

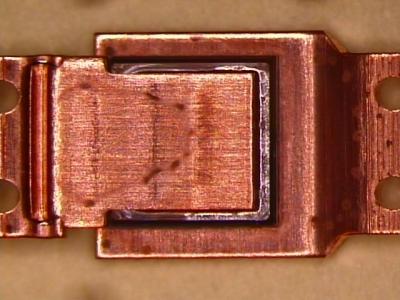

The issue of no-clean solder paste for Power Semiconductor is still hotly disputed, as the failure mechanisms (with the noteable exception of current leakage) are different from those for PCB assembly. For example, wirebonded power packages are unlikely to ever be no-clean, due to the need for cleanliness of the bond-pads, while some customers are using ultralow-residue no-clean die-attach solder paste and manufacturing clip-attach devices without cleaning. The picture on the right shows a device manufactured using Indium 9.32 ultralow residue no-clean solder paste, that has been used for over a year in a no-clean Power Semiconductor application by Asian customers.

I don't think we will ever see a complete absence of cleaning in Power Semiconductor solder paste, as its "non-value-added" nature is more often than not outweighed by its "ensure-zero-field-failures" aspect.

Cheers! Andy