The previous post introduced all of the different type of preheaters. The Hot Plate or Platen preheater will be the first type I will discuss.

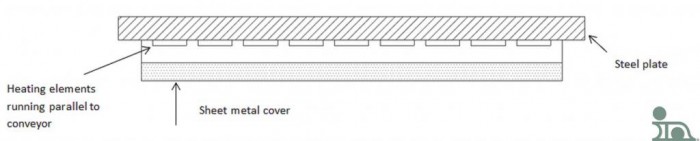

If you are looking for a low-cost option for preheating, the Hot Plate or Platen preheating is the way to go. The preheater consists of an iron plate with strip heaters bolted on the underside, protected by a metal cover. A schematic can be seen below.

The strip heaters are normally positioned parallel to the board motion in the conveyor. In this instance the board would be traveling perpendicular to the screen. The benefit of this is that some of the heaters can be turned on or off based on the width and size of the board being soldered. This can conserve power when needed, and heat more effectively in other instances. The steel plate has to be thick enough to provide even heating. So the power savings are marginal at best.

Advantages:

- Virtually self-cleaning: any buildup of residues will burn off and not affect the heating capabilities

- Unaffected by minor environmental changes (such as opening the machine doors)

- High Thermal Mass

- Low cost

Disadvantages:

- Inefficient use of electrical energy

- Requires considerable time to reach a steady temperature

This type of preheater is ideal if the soldering parameters do not change much during production. Waiting for the plates to reach equilibrium can become a problem in the assembly process because, when a machine is not operating the line stops. A way to mitigate this problem is to adjust the conveyor speed for the different sized boards. This will, however, create a situation where there is a compromise between throughput speed and preheat temperature. This compromise will be ideal compared to waiting for the preheaters to change temperatures unless the assemblies are tightly packaged, or the assemblers are using multilayer boards.

Next week I will be discussing Cal Rod preheaters.

*This is the third post of the twelve piece mini-series entitled Preheating. This is the second mini-series which is part of the larger program entitled Wave Soldering (A Segmented Synopsis).