Folks,

A short time ago, I posted on how to size a reflow oven. I mentioned that I had developed a spreadsheet to perform the calculations. There seemed to be some interest in the spreadsheet, so I thought I would write this post on how to use it.

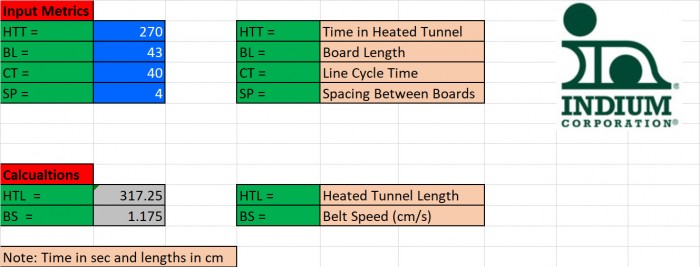

Let’s assume you have a PWB of length 43 cm and you want a spacing of 4 cm between boards. After reviewing the solder paste specification, you determine that your PWB needs 270 seconds in the heated tunnel. The cycle time of the PWBs coming from the placement machines is 40 seconds. To use the software, enter these metrics in the blue cells as shown in Figure 1. The results, a heated tunnel length of 317.5 cm and a belt speed of 1.175 cm/sec are shown in the gray cells.

Figure 1. The data input are in the blue cells and the results, the heated tunnel length and belt speed, are in the gray cells.

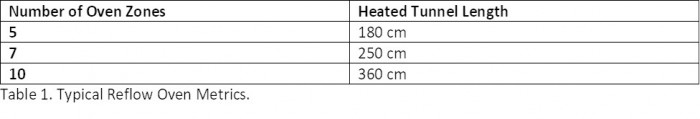

Table 1 indicates that since you need a tunnel length of 317.25 cm, you will have to use a 10 zone oven.

Your board spacing will be more than 4 cm with a 10 zone oven, but this distance will automatically be determined by the belt speed and cycle time.

If you are interested in a copy of the software, send me an email at rlasky@indium.com.

Cheers,

Dr. Ron