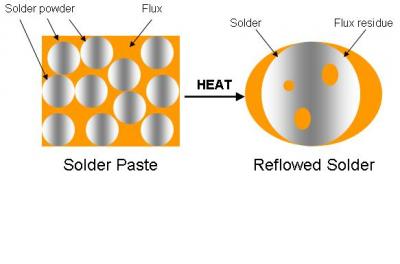

Most people are aware that solder paste is a mixture of solder powder and a flux vehicle. The flux has several functions, but the most important ones are:

1/ Controlling the rheological properties of the paste (dispensing / tack / printing / stability)

2/ Removing oxides from metal surfaces during reflow.

Solder paste is supposed to stay where it is deposited, but occasionally it can turn up after reflow in unexpected places; sometimes a long way (maybe even inches) from where it is supposed to be. This is called "solderspatter" or "soldersplash" (Figure 1). The first step in eliminating solderspatter is to investigate contamination prior to reflow. For a dispensing solder paste, contamination may occur due to "tailing" of the solder paste between deposits. For a printing process, it may be due to bottom-side contamination of the stencil. If this comes up blank, it is time to investigate the reflow process.

Contact contamination within the oven is unlikely, but once all the obvious sources of contamination, such as indexers or edge conveyors, have been checked and cleaned, it is often found that the problem has not been eliminated. The causes of this remaining solderspatter are not clear, but it has been found that two of the important control variables are lot number of the substrate and oxygen level during reflow. Low oxygen levels can actually 'turn on' the defect.

In theory, solderspatter may result from flux decomposition, or rapid volatilisation, of flux or other materials on the surface of the substrate. However, it does not appear to be related to any of the following:

i./ solder paste type or lot number

ii./ relative humidity or

iii./ time paste is left exposed to air

The usual explanation of solderspatter resulting from solvent evaporation, or absorbed moisture in the solder paste itself does not therefore seem to fit here. What may be happening is that during the reflow process, the solder paste goes through "phase inversion" (Figure 2). That is, the flux goes from being the "continuous phase" to being the "discrete phase", while the solder goes the other way - from a high surface area powder to a minimal surface area reflowed joint. The driving force for reflow is the standard potential-energy minimization, from liquid-solid surface-wetting, and liquid-only surface tension.

A simple equation has been derived, to calculate just how high in the air a reflowed solder paste deposit will project a single unreflowed sphere. The answer will surprise you: send me a note and I'll send you the paper.

Cheers! Andy