Michel writes:

Dr. Ron, when if comes to SMT printing of solder paste, why do some people use the five-ball rule for rectangular apertures and the eight-ball rule for circular apertures?

Michel:

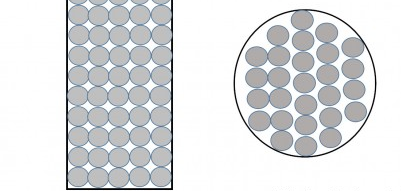

The “Five Ball Rule” is another metric that SMT assembly industry leaders believe, but it is difficult to find its origin. It states that when selecting a solder paste, five of the largest solder balls should be able to fit across the width of the smallest rectangular stencil aperture. See Figure 1a for a 0.2mm wide rectangular aperture.

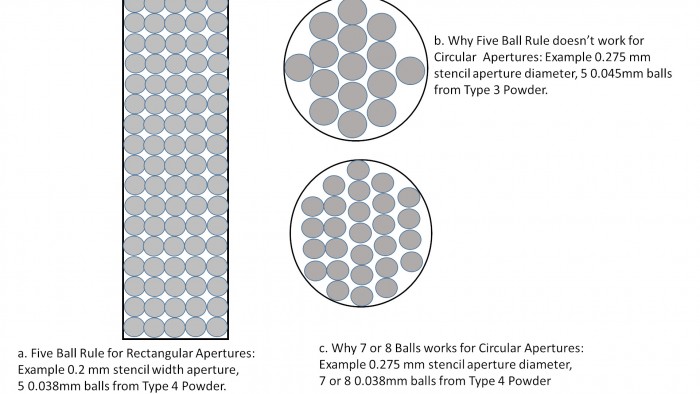

Typically, the largest solder ball diameter is assumed at the 90th percentile. See Figure 2. So, in this example, a type 4 solder paste would fit the five ball rule as the largest solder ball is 0.038mm. Five times 0.038 is 0.190mm, just a little less than the aperture width of 0.2mm. It should be remembered that this is a "rule." not a "law." So let's say you had 4.5 balls across the aperture with instead of 5, it would most likely be OK.

Figure 1. A comparison of the Five and Eight Ball Rules

Figure 2. Solder Powder Sizes

A generation ago, the advent of circular apertures to support BGA and CSP packages necessitated a new “rule.” Figure 1b shows why the five-ball rule is inadequate for circular apertures. Although five type 3 solder balls fit along the 0.275 diameter, off the diameter, there is not enough room for many solder balls. Hence, an insufficient amount of solder paste would be printed.

For the same aperture, if a type 4 paste is used, 7 or 8 solder balls span the diameter and the amount of paste printed would be much closer to the volume of the aperture.

For a little more on this topic, see a past post.

Cheers,

Dr. Ron