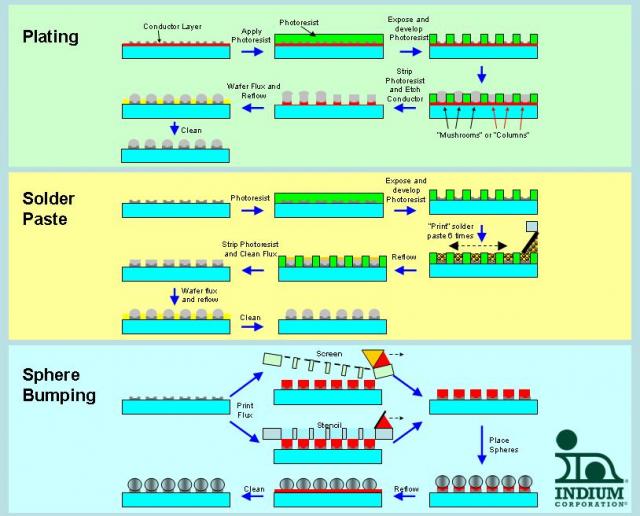

This week's topic is both wafer bumping and substrate bumping with solder paste, and the issue of powder size. I’ve recently been dealing with some issues from customers who are concerned with the question of “how small a solder powder particle do I need, to achieve a certain bump height or bump diameter”? There are some "rules of thumb" on this in the electronics assembly industry, and I'll go into them later. In my next posting, I'll show why they may not be relevant or appropriate for the standard waferbumping process.

To begin: there are lots of ways of forming deposits of solder in a small form factor, and solder paste printing remains one of the most reliable, although yield drops dramatically at below 120microns pitch (some say 100microns).

If you are stencil printing solder paste, there are two guiding principles:

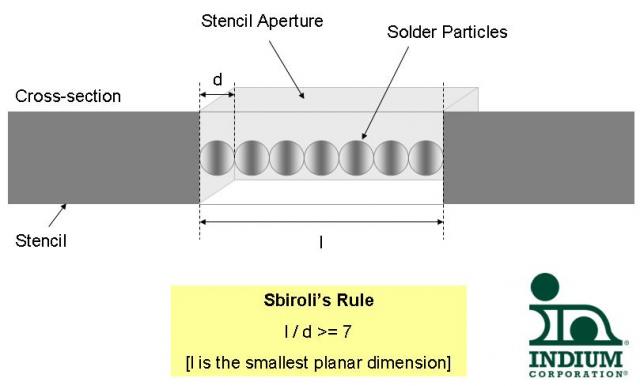

1/ Sbiroli’s Rule: The width of the stencil opening must be 7 particles or greater. By the word “particle”, we err on the side of caution and refer to the highest controlled particle diameter. For example, in the case of a type 3 paste, this will be around 45microns, although you should refer to my previous posting on the subject of powder size standardization (for types 5,6,7 and so on) and the poor state that that is in.

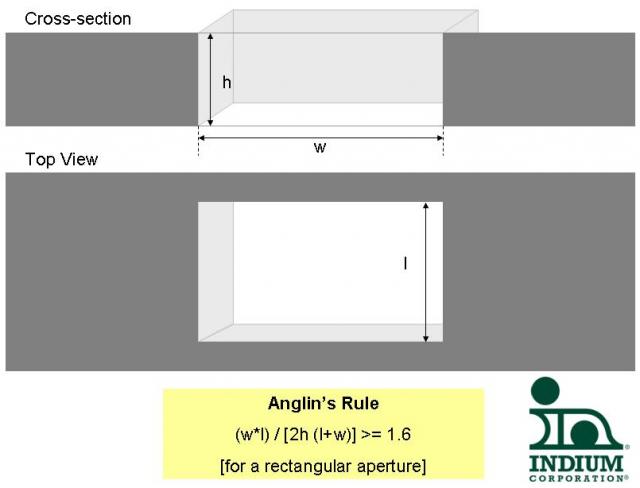

2/ Anglin’s Rule: You should not exceed an aperture ratio of 1.6. The aperture ratio being a measure of the aperture wall area to “open area”. As I showed in a previous post, this rule originates from boundary-layer-type considerations of release from the stencil walls by the pseudoplastic/thixotropic solder paste material.

What if you are NOT stencil printing? The Flip Chip International (FCI) “drive in” process, which uses a developed photomask as a kind of “in situ” stencil for solder paste, allows for 5 or 6 print strokes using a soft squeegee to ensure that each aperture is filled. There are no problems here with stencil release, so how do we go about thinking of what particle size is required in this and similar processes? I think I have the answer: more next time.

Cheers!

Andy