The telecom industry relies heavily on Telcordia (Bellcore) testing to determine the electrical reliability of no-clean solder flux residues. There are many aspects of Telcordia testing that mimic IPC flux classification test methods. One significant area of divergence between Telcordia and IPC is in SIR (Surface Insulation Resistance). The test pattern used for Telcordia SIR has substantially tighter spacing than the SIR pattern used for IPC SIR. The traces and spacing on a Telcordia SIR pattern are both .318mm (.0125”) wide; whereas, for an IPC SIR pattern, the traces are 0.4mm (.016”) wide with 0.5mm (.020”) spacing. Because of the tighter spacing, some argue that Telcordia SIR is more difficult to pass than IPC SIR. However, the Telcordia SIR is a quicker test, 96 hours versus IPC’s 168 hours, therefore, not adding as much of the element of time or aging to the test. A longer test allows more time and opportunity for dendrite formation, thereby, perhaps providing a truer picture about the corrosive nature of a flux (residue).

Telcordia and IPC ECM (Electro-Chemical Migration) testing is, for all intents and purposes, identical. As a matter of fact, most, if not all, third-party test labs do not discriminate between the two. Both IPC and Telcordia ECM use the tighter spaced pattern of .318mm (.0125”) wide traces and spacing; and, both tests are for ~21 days (500 hours). ECM testing is similar to SIR in many ways, but the longer test duration is better-suited for detecting ECM issues such as dendrite formation. The long test duration, coupled with the tight spacing, is more likely to catch something amiss with the electrical reliability of a flux (residue).

So, a flux (residue) that has passed and been qualified per Telcordia SIR and ECM has really been put through its paces. It would be good enough for a no-clean flux (residue) to pass these tests in the activated (reflowed) state. But, the level of confidence in electrical reliability from a flux (residue) that passes Telcordia SIR and ECM in the un-activated (un-reflowed) state is substantially higher. At that point, all electrical reliability concerns for a flux (residue) virtually disappear. One may question if such fluxes really do exist. The good news is that they do! Below are the Telcordia ECM and SIR data of a flux which happens to be a ROL0, per J-STD-004B, solder preform flux coating called LV1000.

Telcordia/IPC ECM

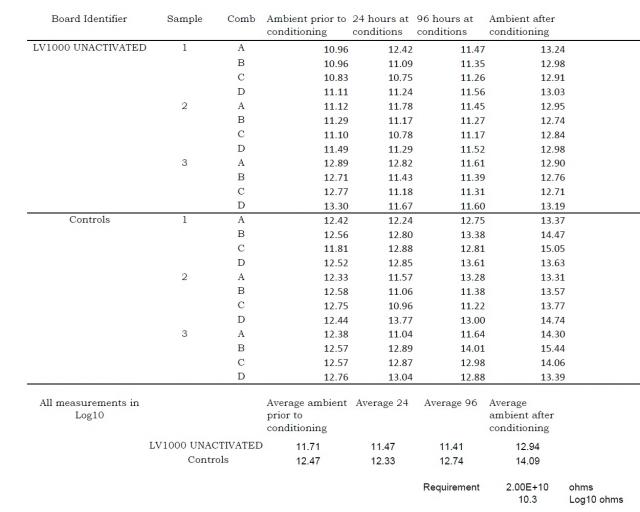

Telcordia SIR