I’m just back from Malaysia, where I visited one of our larger customers who has been using our high-lead (high-Pb) dispensable NC-SMQ75 solder paste for many years. No surprises there, but what many people don’t realize is that the NC-SMQ75 solder paste can be used as a no-clean material in many power die-attach applications. I [ACM] spoke to my friend SzePei Lim [SPL], our Area Technical Manager, based in Kuala Lumpur, about the revolutionary NC-SMQ75 paste:

[ACM] Please tell me about NC-SMQ75. What makes it a unique material?

[SPL] Indium's NC-SMQ75 no-clean die-attach solder paste is one of an emerging class of materials from Indium Corporation based on “ULR” (ultra-low residue) fluxes: these have residue levels of 4% or less after reflow. NC-SMQ75 leaves only about 4%, by weight, of flux: therefore around 0.4%, by weight, of a 90%w/w metal solder paste. This is the lowest residue solder paste we know of that is widely used in the power semiconductor assembly industry. NC-SMQ75 no-clean solder paste is our best seller in the die-attach application on leadframes for power devices, such as clip-on-leadframe and leadframe-based clip-bonded stacked die. It can be applied by either dispensing or printing, and can be reflowed under either a forming gas or a nitrogen environment.

[ACM] What does “no-clean” mean in high-temperature power semiconductor die-attach applications? They are very different from standard no-clean solder paste usages.

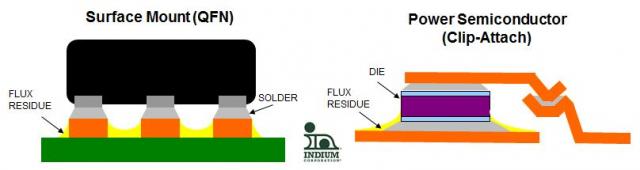

[SPL] There are some big differences: the current flow in power semiconductors is vertical (from top to bottom or vice versa), rather than between adjacent conductors, like in surface mount technology (SMT), plus the package is overmolded with a solid-filled epoxy-based material.

A high voltage and thin die therefore combine to give a significant field strength across the die. A ULR flux with benign, hard residues and low resistivity (good electrical properties) is, therefore, critical. This type of residue also allows for good bonding to the overmolding compound, to prevent delamination during thermal cycling and MSL testing. Customers using this paste in no-clean applications report that, once the reflow profile has been optimized to minimize both voiding and residue levels, the final overmolded component is suitable for use in many different type of application, including automotive.

[ACM] Is there a tradeoff between a ULR no-clean solder paste and reduced voiding?

[SPL] A customer has to be careful to optimize their reflow profile to minimize voiding. That is true for the ULR pastes as well as other types. However, NC-SMQ75 has repeatedly proven itself to be able to reflow with less than 5% total voids in many smaller die applications, especially those less than 10 x 10mm.

[ACM] Solder pastes typically “spit” badly when reflowed, leaving undesirable flux spatter on wirebonding pads. Is it possible to use this as a no-clean paste even in a wirebonded application?

[SPL] Yes. Perhaps surprisingly, these ultra low residue characteristics enable NC-SMQ75 to be used as a true no-clean solder paste, even in the power die-attach application where subsequent steps include wire-bonding. We have experience with several customers, where the design and placement of the paste deposit can be optimized to minimize the issue of flux spitting onto wirebond pads. And we can provide guidance where needed. This usually works best in applications where there are fewer than 5 wirebond pads per component.

[ACM] Are there any special precautions that need to be taken when evaluating the NC-SMQ75 for no-clean power applications?

[SPL] Power semiconductor device types are undergoing rapid evolution, as the electrical demands of the devices drive customers away from thin wirebonds towards more robust copper-clip-based applications. Die are also becoming thinner: down to 50 microns, in some cases. As with all applications where there is no single set of applicable industry standard test methods, large-scale testing of multiple batches of components and paste batches is recommended, to establish sufficient data to allow clear decisions to be made on the usefulness of the solder paste in the final assembly process.

Occasional incompatibility with a specific type of semiconductor die may be seen, but it is something that we know about as a rare issue. Indium Corporation technical personnel can assist during the evaluation process, to guide customers on what to look out for. Additionally, I, and several of my colleagues, have extensive experience using NC-SMQ75 in no-clean die-attach applications. The compatibility of the final reflowed flux residue with different types of overmolding compounds is usually very good, with the Sumitomo G700 series appearing to be one of the best types, although Hitachi, Panasonic, and others may also be suitable.

Customers using a standard convection oven modified for high-temp applications need to ensure the N2 flow rate is stable and that there is a controlled, low-ppm oxygen level throughout the oven.

[ACM] I understand that there are new, lower voiding, ultralow residue, no-clean pastes being developed for power semiconductor devices: is that true?

[SPL] Yes, our US- and China-based research and development teams, led by Dr Ning-Cheng Lee, are developing even more solder pastes for no-clean die-attach in this market. Some of these may also be applicable for our new HTPbF (high-temperature lead-free) drop-in die-attach paste, the BiAgX® material, but that is still a few months away from implementation.

SzePei, thank you for teaching us. Many thanks for your gift of mooncake last month, and please enjoy your Zhongqiu celebration!