Folks,

Let’s assume you are trying to improve the productivity of your SMT assembly lines. You work at a facility that manufactures high volume products with a high mix. The first aspect of your process that you attack is stencil printing. You find that your current paste stiffens up when the printing process pauses. So, after a pause, you have to wipe the solder paste off of the board and reprint the board.

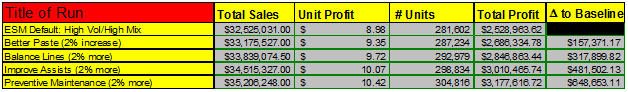

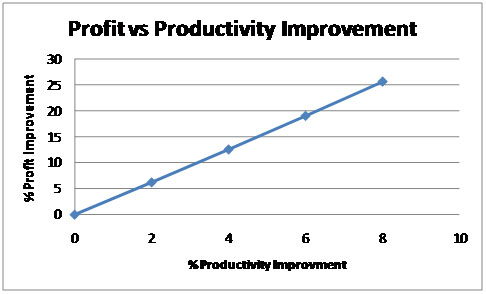

Let’s then assume that you replace this paste with a better one that has good response to pause (i.e. you don’t have to reprint a board after a pause). Let’s also assume that this elimination of reprinting boards results in a modest increase in productivity, say 2%. In other words, you are able to process 2% more boards in the same amount of time. No big deal right? Hardly matters? Wrong! In a typical assembly facility, a 2% increase in productivity results in more than a 6% increase in profits!

You continue working and garner 2% more increase in productivity by balancing your placement machines, improving assist time, and developing a preventive maintenance plan. You have now increased productivity by 8%, but profitability increases by more than 24%!

The calculations that support these conclusions, from ProfitPro,™ are shown as a graph of profitability increase versus productivity increases. All of these calculations support the “Law of Exponential Profits.” This “law” (OK it was developed by me, so maybe it isn’t a law) states that an incremental (e.g. 2%) increase in productivity results in an exponential (e.g. 6%) increase in profits. The results will vary depending on the assembly facility, but the basic idea is always true.

The calculations that support these conclusions, from ProfitPro,™ are shown as a graph of profitability increase versus productivity increases. All of these calculations support the “Law of Exponential Profits.” This “law” (OK it was developed by me, so maybe it isn’t a law) states that an incremental (e.g. 2%) increase in productivity results in an exponential (e.g. 6%) increase in profits. The results will vary depending on the assembly facility, but the basic idea is always true.

The bottom line: Investing in productivity always pays.

Cheers,

Dr. Ron