Applications: Soldering

Solder Redefined Video 2: Die-Attach

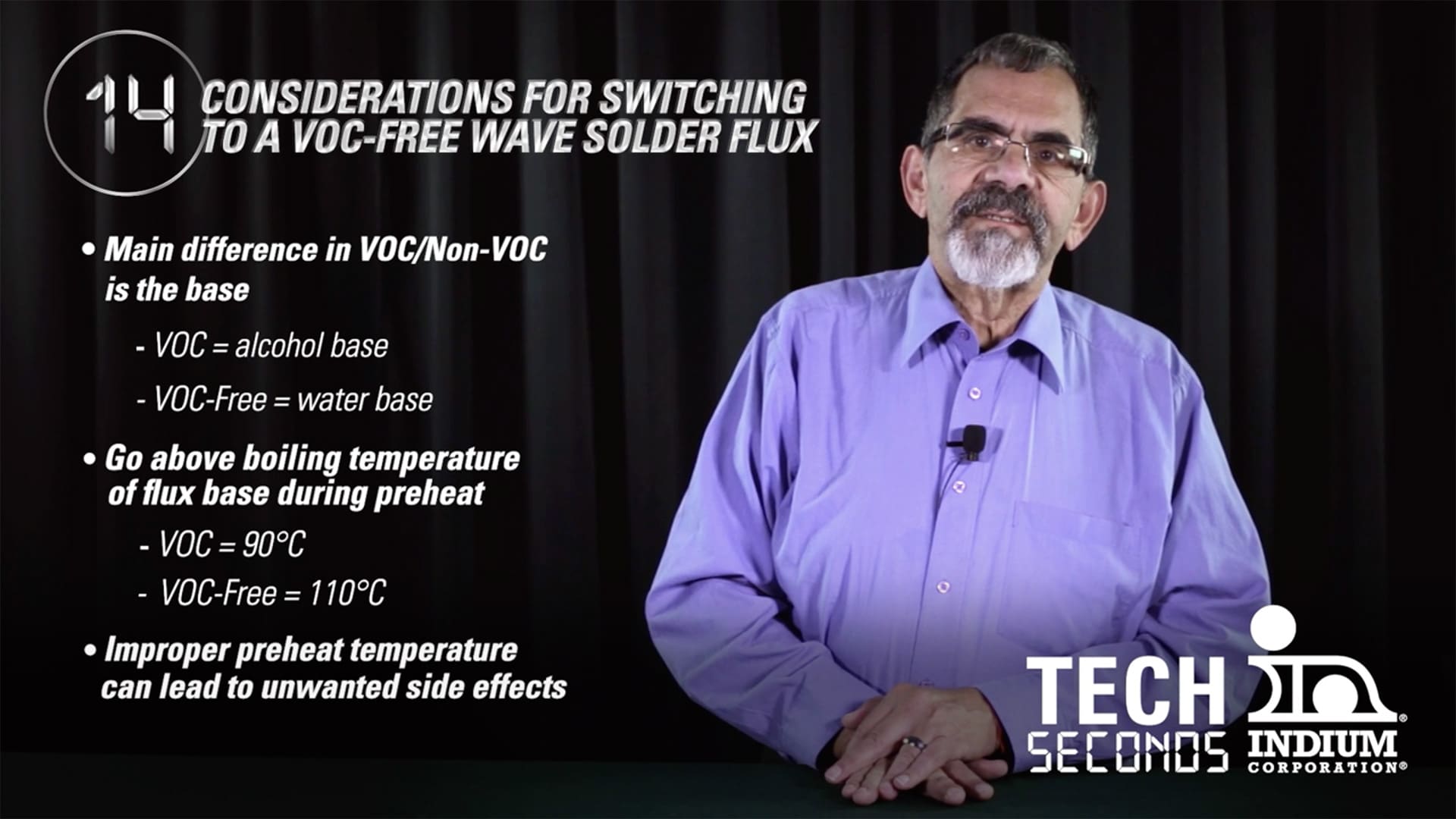

Tech Seconds with Phil Zarrow: Considerations for Switching to a VOC-Free Wave Solder Flux

Tech Seconds with Phil Zarrow: Choosing a Solder Paste Supplier

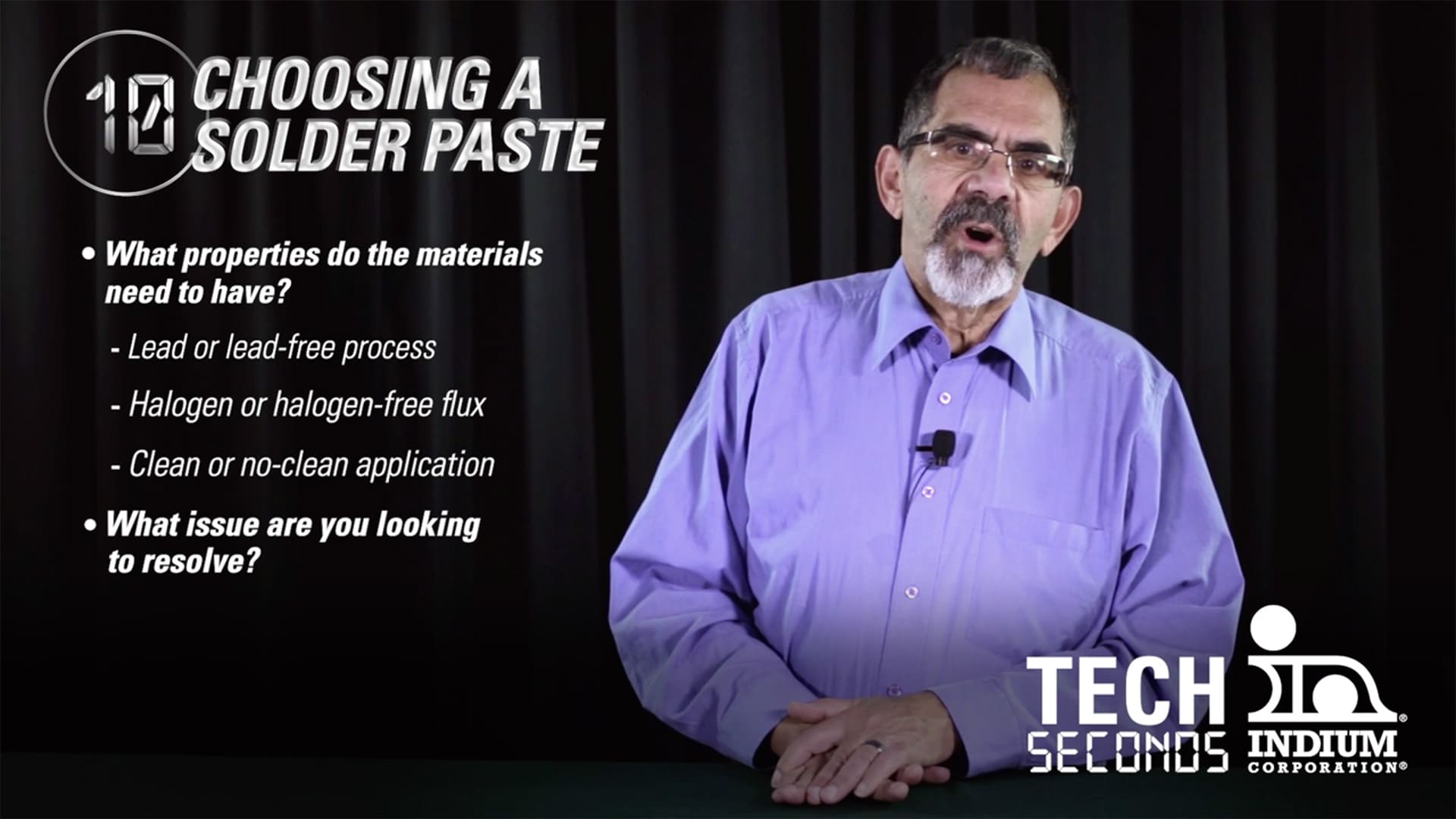

Tech Seconds with Phil Zarrow: Choosing a Solder Paste

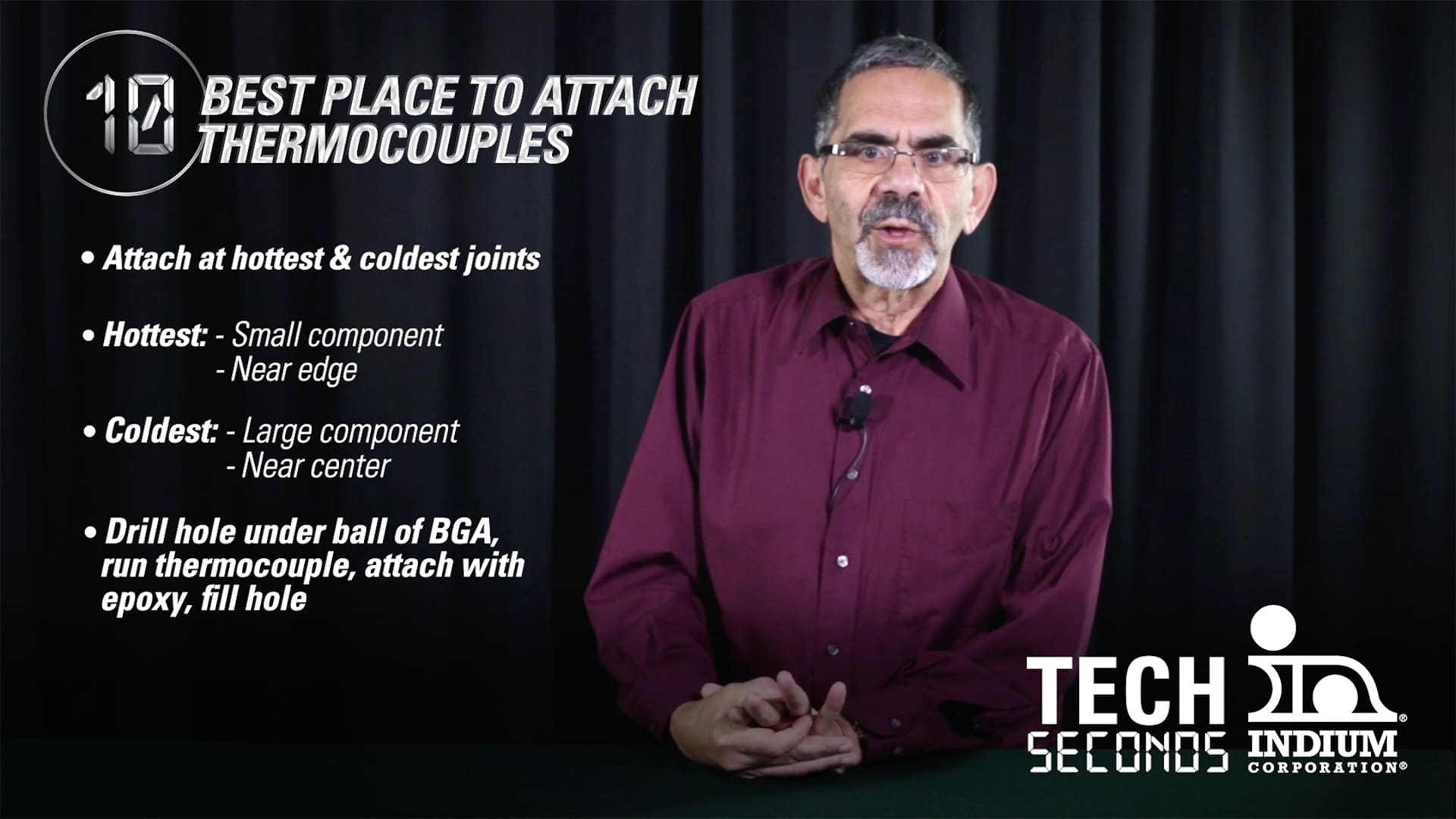

Tech Seconds with Phil Zarrow: Best Place to Attach Thermocouples

Surface-Mount: Reflow Soldering & Thermal Profiles

Surface Insulation Resistance (SIR) and Flux Designation (ROL) Defined

Solder Redefined Video 4: Baseplate to Heat-Sink

Solder Redefined Video 3: DBC Substrate to Baseplate

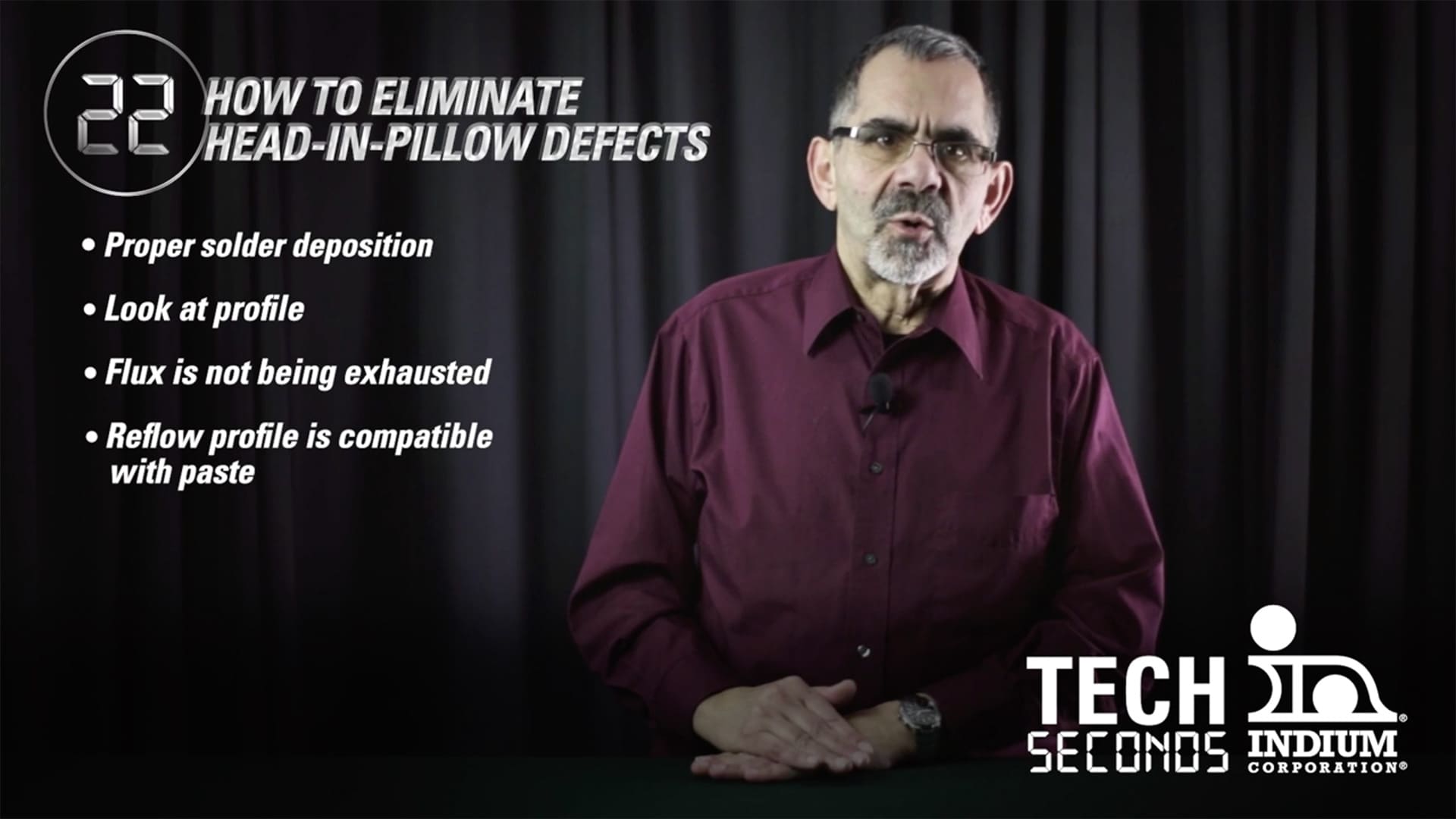

Tech Seconds with Phil Zarrow: How to Eliminate Head-in-Pillow (HIP) Defects

Solder Redefined Video 1: Introduction

Solder Paste Storage & Handling Best Practices

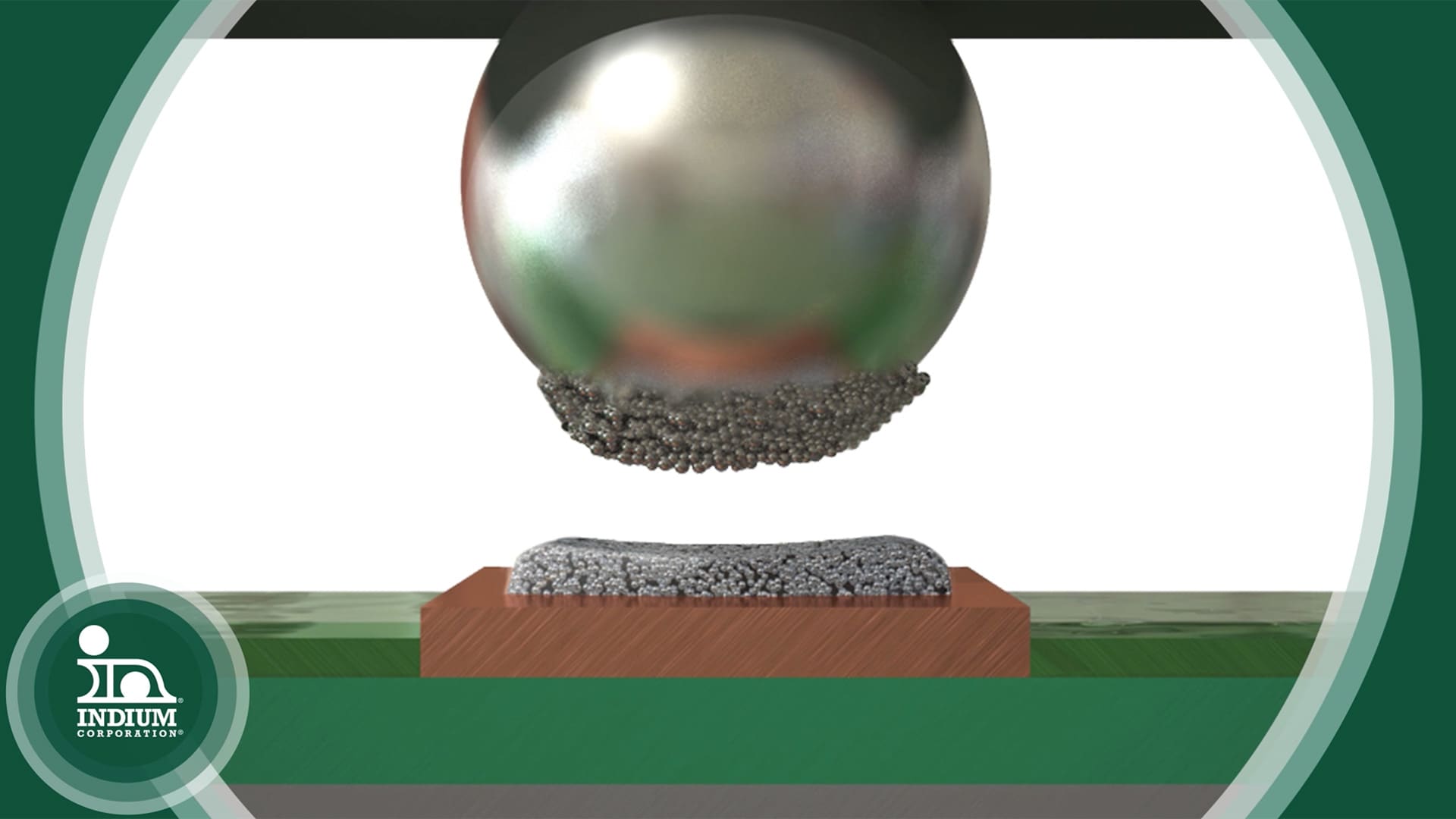

Solder Fortification for Electronics Assembly

Solder Fortification

SMT Wave Soldering: WaveCoach® Helps Optimize Profiling

SMT Reflow Profiling: Using ReflowCoach®

SMT Processes Certification

SMT Line Balancing Using LineCoach® Software

Tech Seconds with Phil Zarrow: How to Select Wave Flux

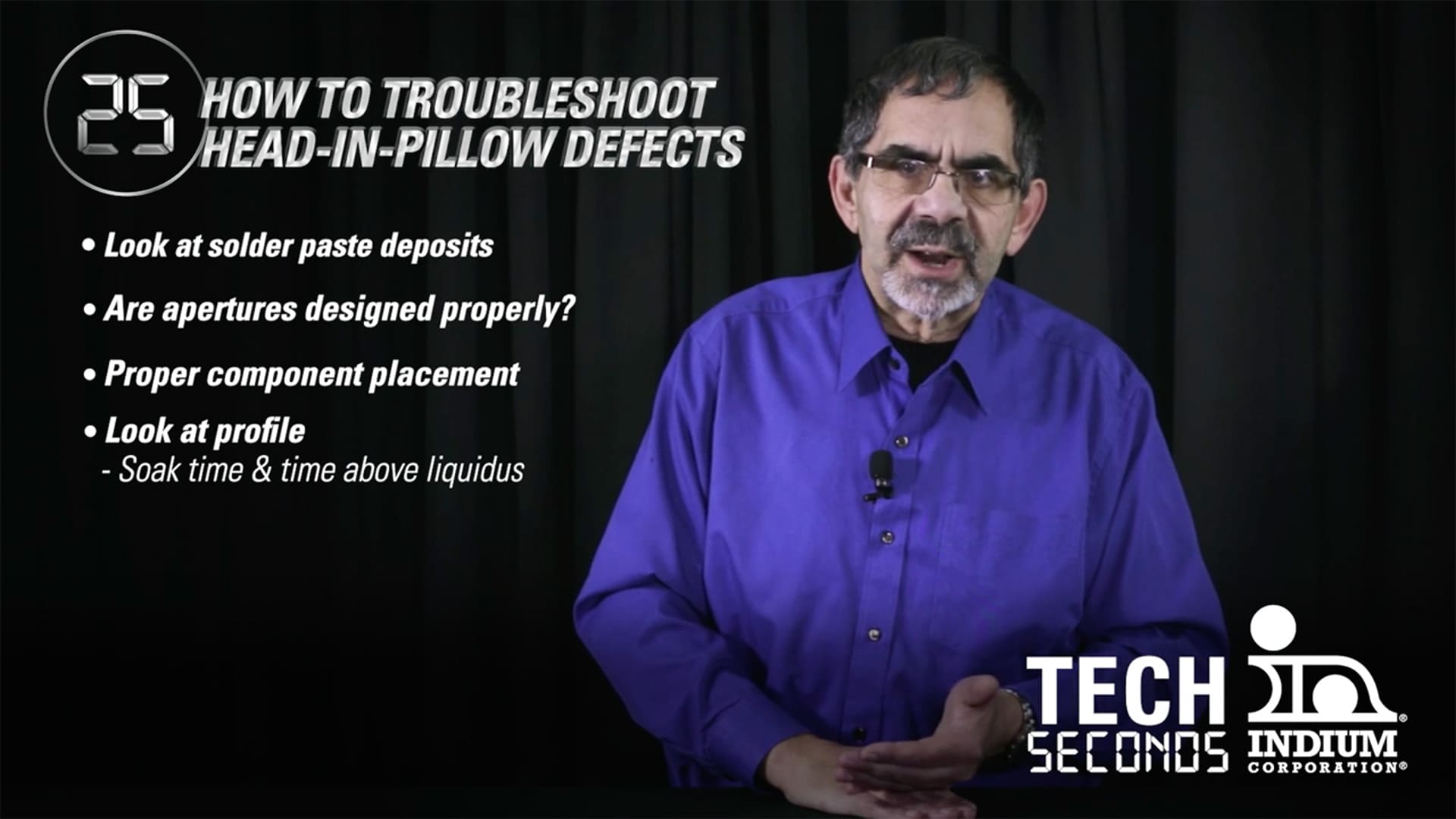

Tech Seconds with Phil Zarrow: How to Troubleshoot Head-in-Pillow (HIP) Defects

Tech Seconds with Phil Zarrow: Kapton Tape for Reflow Profiling

Tech Seconds with Phil Zarrow: Paste Storage & Handling: Ambient Temperatures

Tech Seconds with Phil Zarrow: Paste Storage & Handling: Leftover Paste

Tech Seconds with Phil Zarrow: X-ray Analysis Electronics Assembly

Tech Seconds: Troubleshooting Voiding

Tech Seconds: Voiding - Symptom or Defect?

Tech Seconds: When to Use a Shoulder Profile

The Correct Formula for Solder Alloy Density

The Difference Between Halogen and Halides

We Know SMT: Stencil Printing

When to Use Nitrogen in SMT Wave Soldering

Why Solder Paste is Not a Commodity: Properties that Make a Superior Solder Paste

Defects Eliminated. Reliability Delivered.

Design Solutions for Engineered Solders

Importance of Profiling a Reflow Oven

How to Properly Use Cp and Cpk in SMT Assembly

How Process Variables Affect Variation in QFN Voiding

How NanoFoil® is Used in Soldering Applications

Gold-Indium (AuIn) Alloys for High-Reliability Braze Solutions

Exploring the Wet Gold Technique to Measure Precious Metal Content

Electrical, Thermal, and Mechanical Reliability of Electronics Assembly

Effect of Reflow Environment on No-Clean Residue and Surface Insulation Resistance (SIR)

Improve SMT Stencil Printing using StencilCoach®

Calculating Oddly Shaped Aperture Area Ratios

Avoid the Void®: Voiding in High-Temperature Soldering

Avoid the Void®: Beyond QFN Voiding

Avoid the Void® Common Causes of Voiding in Electronics Assembly

Avoid the Void®

Autonomous Automobiles: The Ultimate Electrical Reliability Challenge

Assessing Field Reliability and Defect Rates in Electronics Assembly

An Introduction to Particle Size and Printing Smaller Area Ratios

In-Circuit Testing with Fast-Break Residue No-Clean Solder Paste

Indium Corporation: Productivity

Indium Corporation: Profitability

Indium Corporation: Response-To-Pause

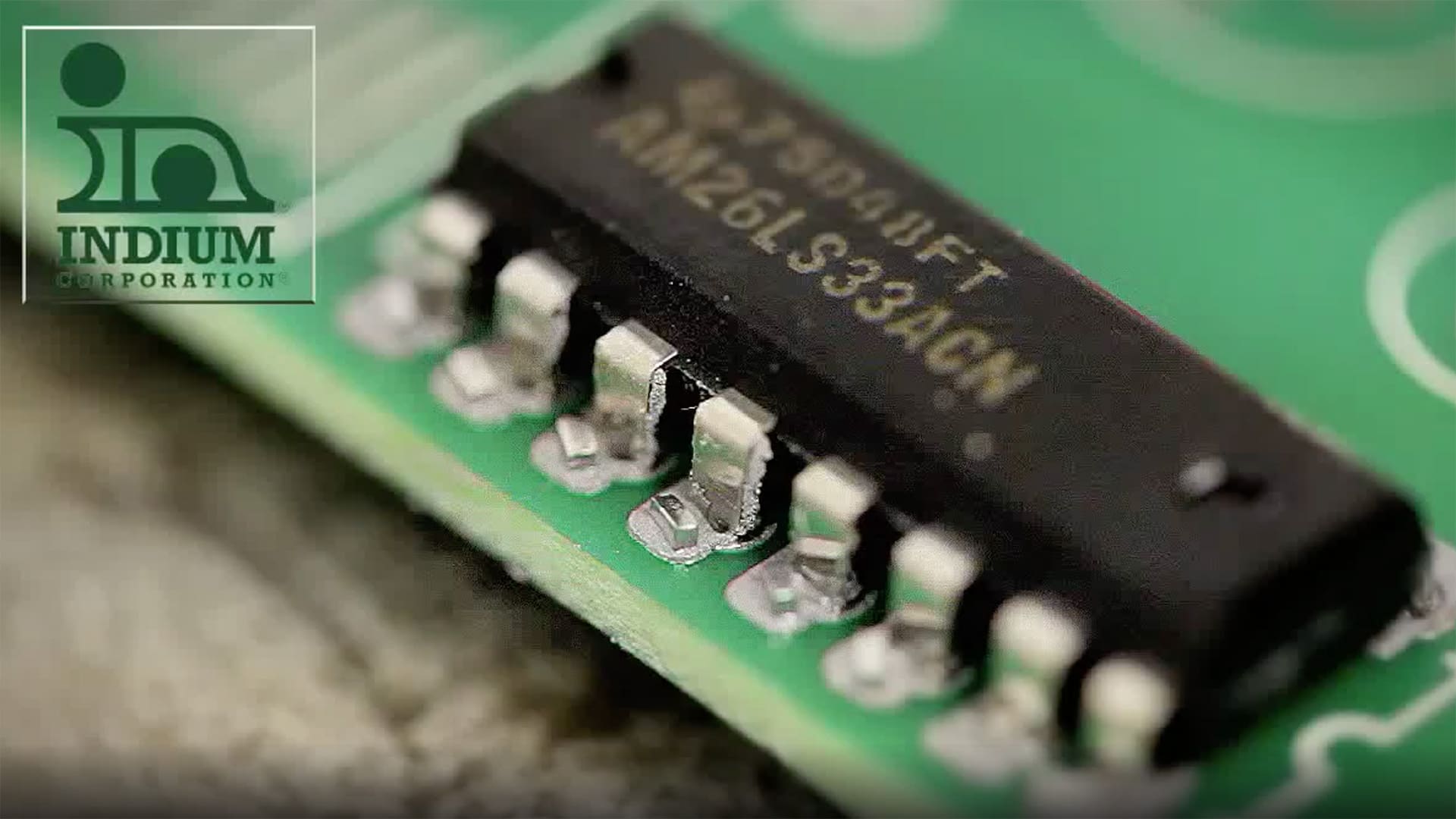

Introduction to Head-in-Pillow and Non-Wet Open Defects

Maximizing Uptime in Electronics Assembly

Minimizing Head-in-Pillow Defect in SMT Assembly

Overcoming the Challenges Associated with Halogen-Free

Printing Differences Between No-Clean and Water-Soluble Solder Pastes

Process Capability: Cpk and Cpu in Relation to Purity of Compounds from Indium Corporation

Process Considerations for QFN Voiding in SMT Electronics Assembly: Part I of III

Process Considerations for QFN Voiding in SMT Electronics Assembly: Part II of III

Process Considerations for QFN Voiding in SMT Electronics Assembly: Part III of III

Reducing Voiding in Bottom Terminated Components Using Solder Fortification® Preforms

RoHS Ten Years Later: The Transition to Lead-Free Electronics Assembly